What is a flour mill?

Edited by: www.immy.cn www.immyhitech.com

A flour mill is a specialized facility or set of machinery designed to transform raw grains—such as wheat, corn, rice, barley, and oats—into flour, meal, or other granular products through a series of mechanical processes. It serves as a critical link between agricultural production and food consumption, enabling the conversion of hard, inedible grains into versatile ingredients that form the foundation of countless staple foods worldwide, from bread and pastries to noodles and cereals.

The history of flour mills dates back thousands of years, reflecting humanity’s ingenuity in adapting to the need for efficient grain processing. Ancient civilizations relied on manual methods, such as mortar and pestle, where grains were crushed by hand. Over time, more sophisticated tools emerged: the Romans introduced water-powered mills, harnessing the energy of rivers to turn large stones that ground grain. Windmills later became iconic in regions like Europe and the Middle East, using wind power to drive milling mechanisms. These early mills were often community hubs, central to agricultural economies and daily life. With the Industrial Revolution, steam-powered mills replaced traditional designs, followed by electric-powered machinery in the 20th century, revolutionizing production capacity and efficiency.

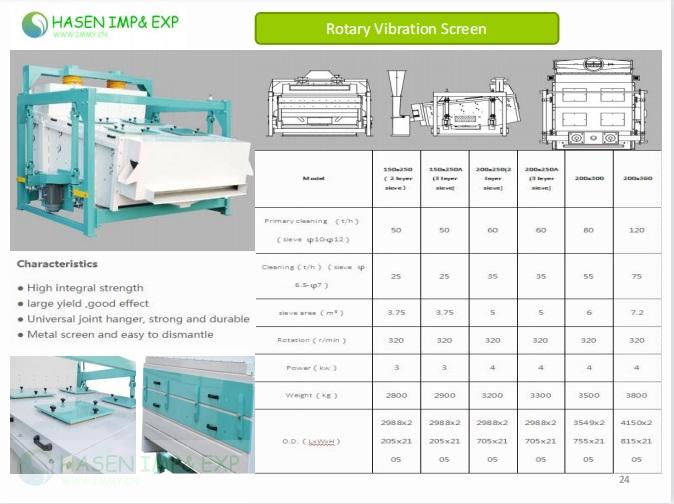

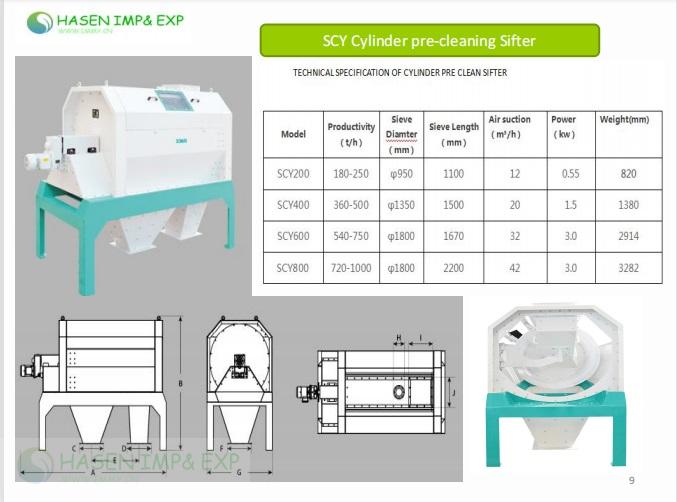

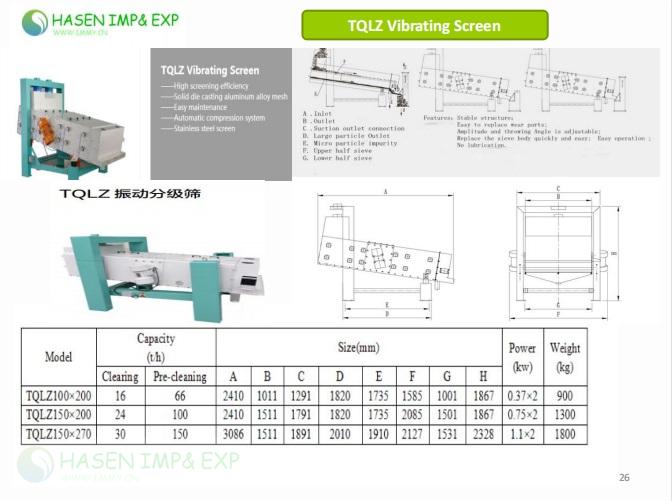

At its core, a modern flour mill consists of several key components working in tandem to process grains. The journey begins with cleaning equipment, which removes impurities like dirt, stones, chaff, and broken grains. This step is vital, as contaminants can damage machinery and compromise the quality of the final product. Machines such as separators, aspirators, and magnetic separators are used to sift, blow, and attract foreign materials, ensuring only clean grain proceeds to the next stage.

Next, the grain undergoes conditioning, a process that adjusts its moisture content to optimize milling. For example, wheat is often soaked in water or steamed to make the bran (the outer layer) easier to separate from the endosperm (the starchy inner part) and germ (the nutrient-rich embryo). Proper conditioning prevents excessive breakage of the endosperm and ensures the bran remains intact, which is crucial for producing high-quality flour with desirable texture and nutritional properties.

The heart of the flour mill is the milling system, where the grain is crushed and ground into flour. Traditional mills used pairs of large, circular stones (millstones), with the upper stone rotating against the lower one to grind the grain. In modern mills, roller mills have largely replaced millstones. These machines use sets of steel rollers with textured surfaces that rotate at different speeds, breaking the grain into smaller particles. The rollers are adjustable to control the fineness of the grind, allowing for the production of various flour types, from coarse whole wheat to fine all-purpose flour.

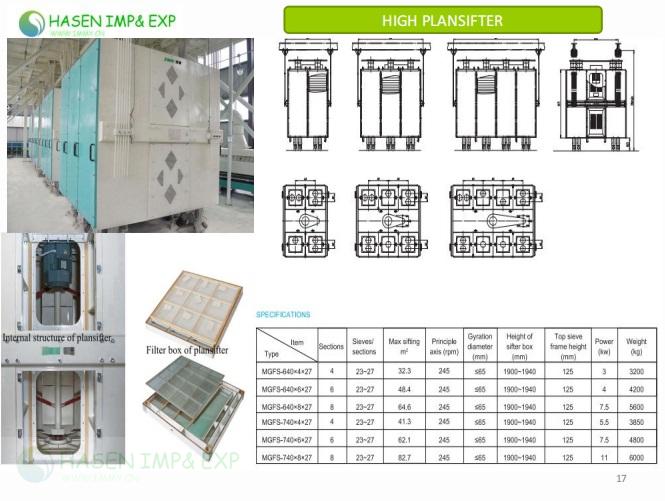

After grinding, the product undergoes sifting to separate different components. Sifters use vibrating screens with varying mesh sizes to sort the flour into fractions: the fine endosperm (which becomes white flour), the coarser bran, and the germ. This separation process enables mills to produce specialized flours—for instance, removing the bran and germ results in refined white flour, while retaining them creates whole grain flour, which is higher in fiber and nutrients.

Flour mills can be categorized based on their scale, power source, and purpose. Small-scale mills, often found in rural areas or local communities, may use manual labor, diesel engines, or electricity to process grains for regional consumption. They typically produce smaller quantities and cater to specific local needs, such as grinding cornmeal for tortillas or millet flour for traditional porridges. Large-scale industrial mills, on the other hand, are massive operations with automated systems that process thousands of tons of grain daily. These mills are equipped with advanced technology, including computerized controls to monitor moisture levels, roller pressure, and sifting efficiency, ensuring consistent quality and high output. They supply flour to food manufacturers, bakeries, and supermarkets on a national or global scale.

In recent years, technological advancements have further transformed flour milling. Automation has reduced the need for manual labor, with sensors and algorithms adjusting processes in real time to maintain optimal conditions. Energy-efficient machinery minimizes power consumption, aligning with global efforts to reduce carbon footprints. Additionally, innovations in sorting technology, such as optical sorters, can detect and remove even tiny impurities, enhancing food safety.

The role of flour mills extends beyond mere production; they are integral to food security and economic development. By processing grains into accessible forms, mills make it easier for communities to access nutritious food. They also support agricultural economies by creating demand for crops, providing farmers with a market for their harvests. In many countries, the flour milling industry is a significant employer, from farm workers supplying grain to factory workers operating mill machinery.

A flour mill is more than just a factory—it is a dynamic system that combines tradition, technology, and precision to transform raw grains into essential food ingredients. From ancient watermills to modern industrial complexes, flour mills have evolved to meet the changing needs of societies, playing a vital role in sustaining human life and driving economic activity. As food systems continue to adapt to global challenges like population growth and climate change, the flour mill remains a cornerstone of food production, ensuring that the grains we grow are turned into the foods we eat.

We do hope to be yoru valued supplier of flour mill machine manufacturer, engineering design and installation, commissioning project provider from China for a lofe long time!

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000