In the world of modern grain processing, WUXI HASEN grain milling roller system stands out as a cornerstone technology powering mills across the globe. As the demand for flour, feed, and other grain-based products grows, understanding how roller systems work — and why they matter — has never been more important. At the heart of this evolution is WUXI HASEN, a seasoned manufacturer based in Wuxi, China, with decades of experience in engineering high-performance milling solutions for wheat, maize, barley, sorghum, and more.

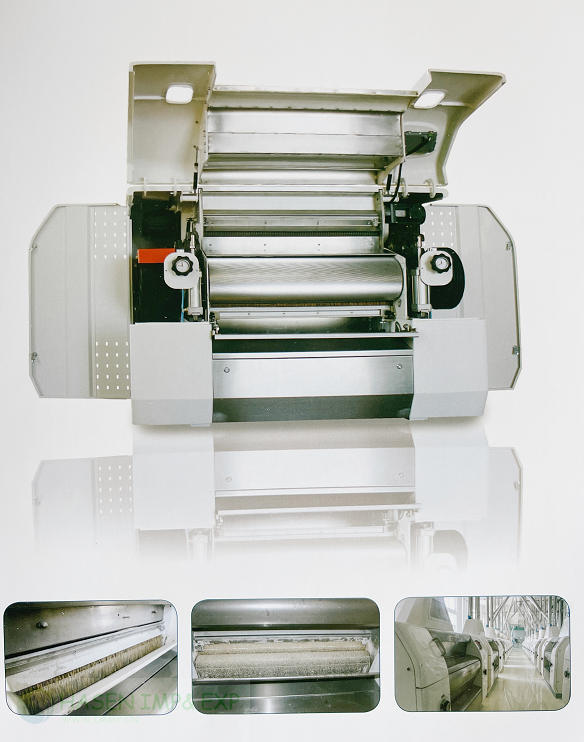

A WUXI HASEN grain milling roller system refers to a series of cylindrical rollers designed to crush and grind grains into flour or meal with high precision and efficiency. Unlike traditional stone-based milling, roller systems use rotating, often adjustable, rollers that apply controlled pressure to split grain kernels into constituent parts — bran, germ, and endosperm — while producing a consistent particle size.

This careful control over grinding helps millers achieve specific product qualities such as fine wheat flour for baking or coarse maize meal for industrial uses.

WUXI HASEN grain milling roller system technology ensures these outcomes through precision engineering and automated controls.

The core design of a WUXI HASEN grain milling roller system revolves around pairs of rollers that create a crushing action by rotating toward each other at different speeds. Each roller pair is responsible for a specific stage of the milling process — from break rolls that separate the endosperm from the bran, to reduction rolls that grind particles down to flour or meal.

What makes WUXI HASEN grain milling roller system exceptional is its modular design.

Technicians can adjust the gap between rollers and change roller surfaces depending on the grain type and desired output, allowing for flexibility in producing diverse products — from fine wheat flour to coarse grits or feed.

1. Precision Grinding and Consistency

One of the biggest benefits of the WUXI HASEN grain milling roller system is the ability to produce uniformly sized particles with minimal variations. Consistency in particle size is crucial for professional millers because it directly impacts product quality — from baking behavior in flour to digestibility in feed.

2. Increased Throughput and Productivity

Thanks to optimized feeding systems and advanced roller mechanics, the WUXI HASEN grain milling roller system handles large volumes of grain efficiently. Whether operating small local mills or large industrial plants, operators experience high throughput with minimal downtime.

3. Energy Efficiency

Energy costs are a major concern in milling operations. The WUXI HASEN grain milling roller system is engineered with efficient motors and mechanical transmission to minimize power consumption while maintaining high grinding performance. This efficiency contributes to lower operating costs and a reduced carbon footprint.

4. Enhanced Durability and Low Maintenance

Using high-grade materials like hardened steel and corrosion-resistant components, the WUXI HASEN grain milling roller system delivers extended lifespan and low maintenance requirements. Quick-change rollers and easy-access parts further reduce downtime during routine checks or overhauls.

Bread and Wheat Flour Production

A WUXI HASEN grain milling roller system is indispensable in wheat flour milling, where controlling particle size and gluten behavior is essential for baking quality. Roller mills separate bran and germ effectively to produce consistent, high-quality flour suited for bread, pastries, and general baking.

Maize and Corn Processing

In maize mills, the WUXI HASEN grain milling roller system provides versatility by offering both cracking and fine grinding operations. Whether producing cornmeal for food products or grits for animal feed, these systems ensure uniform output and high yield.

Sorghum, Barley, and Specialty Grains

The same flexibility applies to barley and sorghum — essential for brewing, distilling, or specialty grain products. WUXI HASEN grain milling roller system tailored solutions help mills process diverse cereals with precision and consistency.

Modern milling technologies are rapidly evolving, and WUXI HASEN grain milling roller system designs are at the forefront of this change. Automation and digital controls now allow operators to monitor key parameters like feed rate, roller gap, and moisture content in real time, maximizing efficiency and reducing waste.

Internet of Things (IoT) integration is also transforming roller systems, enabling smart diagnostics and predictive maintenance — a major advantage for mills striving for continuous operations and minimal unexpected downtime.

The WUXI HASEN grain milling roller system incorporates advanced automation features such as automatic roller gap control and feed regulation. These systems adapt dynamically to changing grain qualities and production demands, ensuring consistency without constant manual intervention. This enhances product uniformity and frees operators for other tasks.

Beyond standalone roller systems, WUXI HASEN grain milling roller system can be integrated into complete milling lines — including cleaning, sifting, and packing machinery — to deliver turnkey solutions for clients worldwide. These customized milling solutions help businesses scale their operations efficiently and with full technical support.

As a global supplier, WUXI HASEN grain milling roller system has been deployed in facilities across multiple regions, enhancing productivity and product quality for small mills and high-output industrial plants alike. Customer feedback frequently highlights increased yields, reduced energy consumption, and improved product consistency as key benefits of these advanced roller systems.

Choosing the right milling equipment partner can make all the difference, and WUXI HASEN grain milling roller system offers several compelling advantages:

Decades of expertise in grain processing engineering

Customizable solutions tailored to your product goals

High-quality, durable machinery built for industrial demands

Advanced automation and IoT-ready technologies

Global support and turnkey project services

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000