For choosing the right Flour Mill Machine in Indonesia can be the difference between a successful milling operation and a costly investment mistake. As demand for high-quality flour continues to rise across Indonesia’s bakery, noodle, confectionery, and food processing sectors, farmers and entrepreneurs are searching for dependable solutions that balance performance, efficiency, and long-term value. One brand that consistently comes up in global searches when Indonesians look for flour mill solutions is WUXI HAEN flour mill machine, a trusted name from China known for its engineering excellence and complete milling systems like those showcased on www.immyhitech.com.

In this comprehensive buyer’s guide, we’ll walk you through the most important factors to consider when selecting a flour mill machine in Indonesia — including which features matter most, how to evaluate capacity and cost, and why choosing a branded solution like a WUXI HAEN flour mill machine makes sense for long-term operations.

The first step in choosing a Flour Mill Machine in Indonesia is defining what you want to process and how much output you need. Milling yield and performance are directly linked to these two questions:

What grain will you mill? Wheat? Corn? Millet? Multigrain?

Your expected daily output (kg or tons per day)?

Quality requirements: standard flour, fine pastry flour, whole grain, etc.

Large commercial operations will require more advanced installations compared to small or medium sized mills that serve local markets. For example, WUXI HAEN’s advanced systems vary from medium capacity units to fully integrated large-scale lines for high daily throughput.

One of the top search intents globally when customers research “flour mill machines” is capacity planning — simply put, ensuring the machine you choose can handle your production goals without bottlenecks.

Small flour mill machine — Suitable for village level or small bakery mills, typically below 50 kg/hour.

Medium scale mills — 50 kg ish to several tons per hour — good for community cooperatives or regional suppliers.

Large flour mill systems — Designed for factories, can produce tens to hundreds of tons of flour per day.

When choosing a Flour Mill Machine in Indonesia, always build in room for growth. A system that barely meets your current needs may become overwhelmed if demand increases.

WUXI HAEN offers customizable capacity solutions including complete EPC turnkey flour mill lines suitable for large-scale operations — helping mills expand without frequent upgrades.

The technology behind a flour mill changes flour quality, consistency, and energy use — major considerations for Indonesian buyers doing online research.

Roller mills are widely used in industrial and commercial flour production due to their:

High precision and uniform output

Scalability for large operations

Ability to produce a range of product grades

This is why the WUXI HAEN flour mill machine is often highlighted in searches — their roller mills are designed for durability and smooth performance in wheat and grain processing.

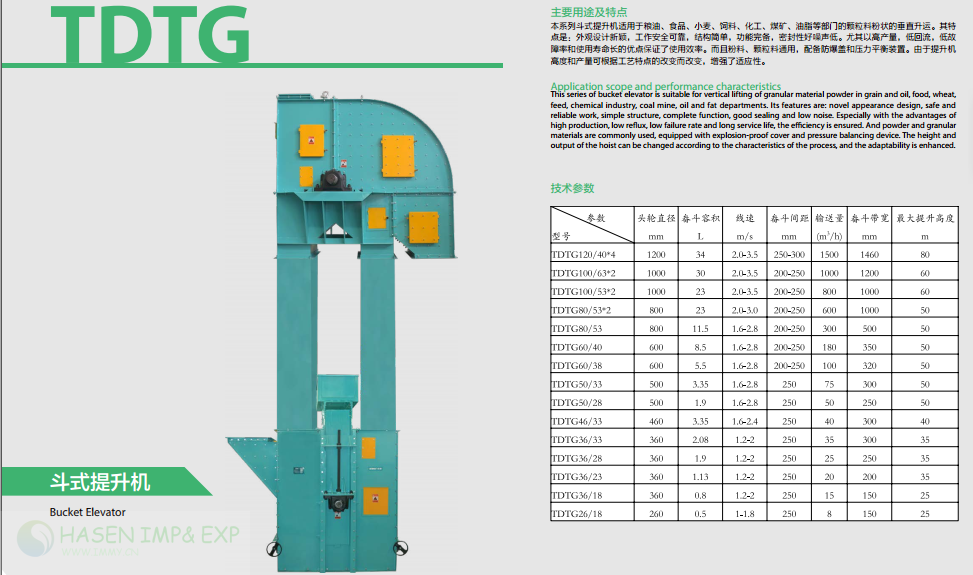

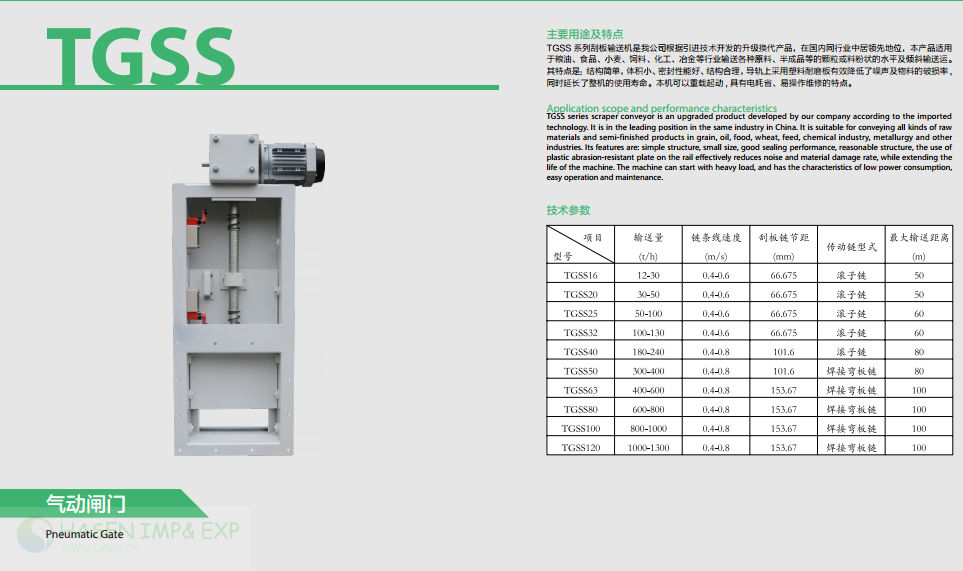

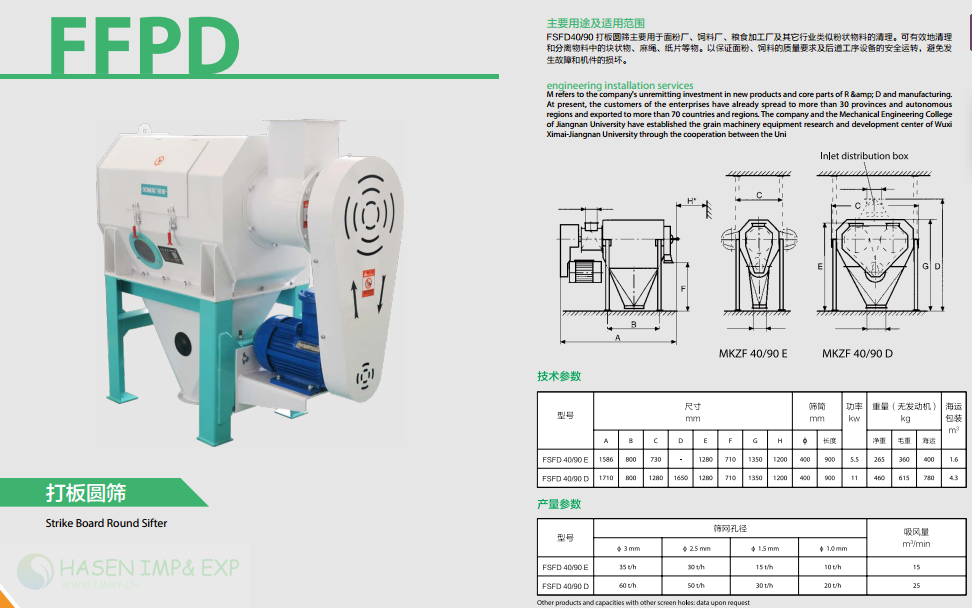

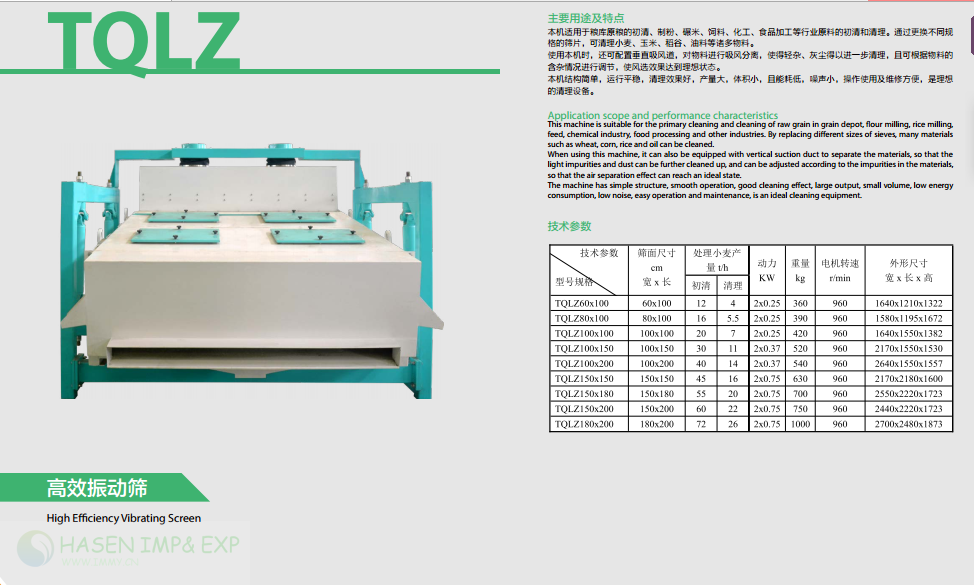

Other features that influence performance include:

High Plansifter for separating particles by size

Purifier to refine flour and remove impurities

Moisture Controller to optimize grain conditioning

Bran Brush to recover residual flour and boost extraction rates

Each of these components contributes to overall performance, which is why many Indonesian buyers looking for “best flour mill machines” pay close attention to full system design, not just the grinder.

Automation can make a major difference in milling operations. Many modern flour mill machines include features such as PLC (Programmable Logic Controller) systems to manage:

Feeding rates

Roller speed and pressure

Sifting stages

Packaging lines

Automation helps reduce labor costs, minimize human error, and maintain consistent product standards — benefits often cited in top-searched guides and industry buying resources.

WUXI HAEN offers options with PLC and advanced control systems to support both less-experienced operators and large automated mills.

When Indonesians search for a flour mill machine online, they often ask: “Is it durable?” This is a key buying consideration that affects long-term reliability and maintenance costs.

Look for mills with:

Food-grade stainless steel contact surfaces: easier to clean, hygienic, and corrosion-resistant.

Robust frame and gearbox construction: essential for continuous operation.

Efficient dust control systems: to protect workers and keep production areas clean.

These are commonly recommended features in industry guides and help ensure your flour mill machine lasts longer with fewer breakdowns. Investing in quality reduces downtime — especially essential in humid climates like much of Indonesia.

Energy is a significant operating cost for flour milling businesses. When comparing machines:

Check motor efficiency ratings

Understand whether the machine requires three-phase or single-phase power

Look for energy-saving drives and systems

Lower energy per ton of flour significantly improves a mill’s profit margin — a topic frequently emphasized in buyer research online.

Many models from brands like WUXI HAEN are built with efficient drive systems and can be adjusted to match Indonesian power supply conditions.

Another top “how to choose a flour mill machine” search theme is serviceability — customers want assurance they can easily get spare parts and support.

Factors to consider:

Availability of spare parts locally or via import

Ease of servicing critical components

Availability of technical support or expert guidance

WUXI HAEN’s global export experience and long-term relationship with clients through training and commissioning means Indonesian buyers can get support even after installation.

Price is critical — but it’s not what you pay upfront that matters most. Savvy buyers evaluate Total Cost of Ownership (TCO):

Price of machine + installation

Operating costs (energy, labor)

Maintenance and spare parts

Downtime losses

Expected lifetime

Well-engineered machines like those from WUXI HAEN typically deliver efficient performance and lower long-term costs due to fewer mechanical issues and better energy use.

Buyers in Indonesia often search about safety standards and food compliance for flour mills. While local regulations vary, always check:

Food safety standards

Electrical and mechanical safety regulations

Dust and environmental controls

Choosing a reputable machine brand helps ensure compliance and reduces regulatory risks.

Selecting the right Flour Mill Machine in Indonesia requires careful consideration of capacity, technology, energy efficiency, durability, and long-term support. Whether you’re building a small community mill or a full industrial-scale plant, choosing a reliable supplier with proven experience is essential.

That’s why many Indonesian mills researching their options online turn to WUXI HAEN flour mill machine solutions — known for complete turnkey systems, high-quality engineering, and adaptability for various grain types and production scales.

For expert guidance and premium wheat flour mill machine from China tailored to your Indonesia project, please contact WUXI HASEN through their official website: www.immyhitech.com

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000