Dryer of flour bran in grain and oil, feed industries. www.immyhitech.com

This kind of dryer for flour bran germ (food powder) type of material only, Special designed for flour, bran and wheat maize germs

to ensure produce finest quality of flour bran and germs.

➢ Programmable logic control system to ensure stable drying effect.

➢Unique drying tunnel and spontaneous steam design, prolong drying time, energy-saving effect is remarkable.

➢Lower drying temperature, no change in material color and quality after drying.

➢ Conduction and airflow mixed heat transfer mode, the material is heated quickly, uniformly and sufficiently.

➢The temperature of the material after drying during the cooling process is close to the ambient temperature, and the

low temperature packaging is conducive to storage.

➢ Program fault self-test, stop abnormal equipment and alarm to prevent equipment damage.

➢ Humanized parameter setting, suitable for more milling processes.

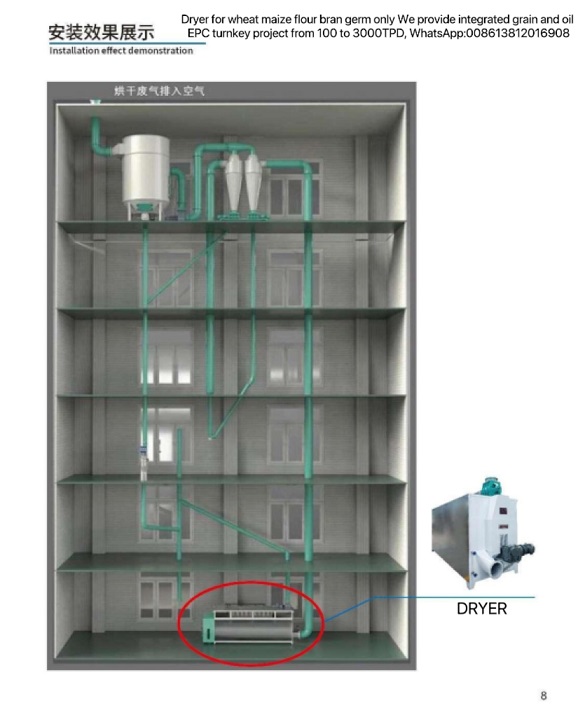

The main components of the drying system: automatic valve, dryer, air closer, fan, dust collector, pulse air flow drying pipe,

pulse air flow cooling pipe, drying cyclone, cooling cyclone, chute, air duct.

Pneumatic valve controls whether the material enters the drying system.

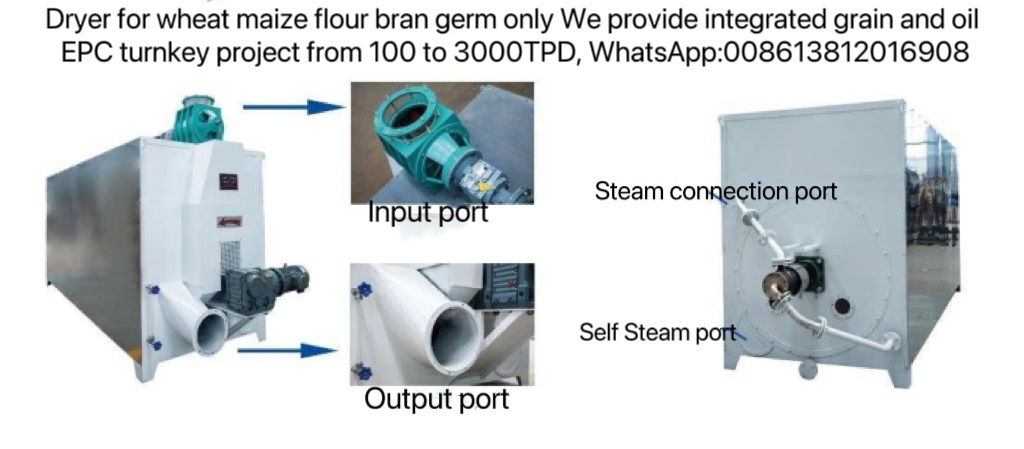

Dryer is a device that evaporates the water in the material.

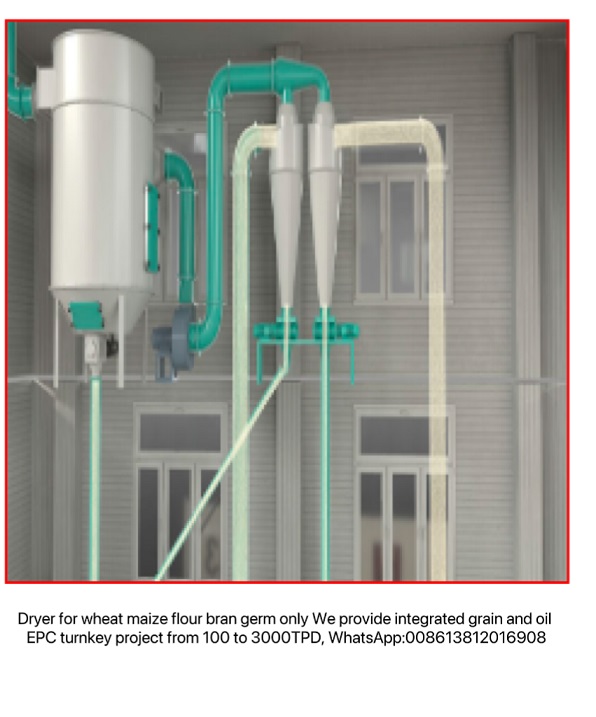

Pulse air flow drying tube is used to separate the material from the water evaporated in the material.

Drying cycloneis used to separate the material and the air for drying.

Pulse air flow cooling pipe uses fresh air to cool the material, to ensure that the material packing temperature is 1-3 degrees Celsius

higher than the ambient temperature.

Cooling cycloneis used to separate materials and cool air.

Air closer are used to seal air through the material.

Fans power the flow of air throughout the system.

The dust collector is used to reduce the dust content of the exhaust gas to be discharged into the atmosphere.

The chute is used to transport materials into the corresponding equipment.

The air duct connects the cyclone, the dust collector and the fan, which is the channel of air and transmits the power of the fan.

Host and valves, equipment, pipelines, etc

Feed valve, dryer, pulse air flow drying pipe, drying discharger, pulse air flow cooling pipe, cooling discharger, fan, damper,

dust collector.

Temperature sensor

Each set of dryers has 5 temperature sensors, which can reflect the temperature of each key part to the screen in real time; The

measured temperature is compared with the set temperature to control the heater output power; Monitor the temperature of critical

areas to ensure that the equipment is operating at a safe temperature.

Level sensor

Each set of drying unit has 4 material level sensors, which monitor whether the key position of the pipeline is blocked, and transmit

the material level signal to the PLC to participate in the control to ensure that the equipment is not overloaded due to material plugging.

Automatic control cabinet

The automatic control cabinet is the control center of the drying system, and all equipment operation, valve action, fault alarm and

shutdown are controlled by it.

Equipment on-site control box

The equipment that can be controlled on site in the system includes: dust collector scraper motor, dust collector air closure motor (2),

fan motor, damper solenoid valve (AC220V), discharger motor, feed valve, solenoid valve (AC220V), dryer motor.

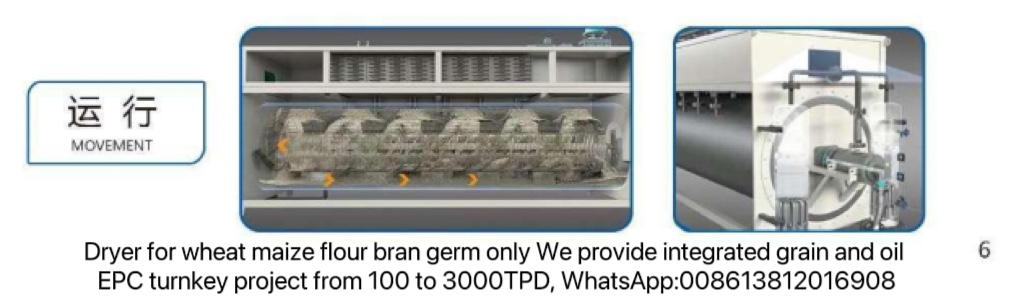

box is in the upper part and the drying drum is in the lower part. The air is heated by the air preheating box and fully mixed with the material

in the drying drum to contain the water evaporated from the material. The drying drum is the device that plays the main role in the whole

drying process, which provides heat for the evaporation of water in the material, and at the same time allows the material and air to be fully

mixed, so that the water inside the material evaporates into water vapor.

The inner cylinder and outer cylinder of the drying cylinder provide heat for the evaporation of the material moisture continuously and

quickly when the material passes, so that the moisture inside the material diffuses to the surface of the material, and the material and the

surrounding air come out of the drying drum into the pulse airflow drying tube Due to the disturbance of the airflow, the moisture on the

surface of the material quickly diffuses to the surrounding air and separates from the material, and the material at the drying Sacron is

separated from the air containing a large amount of water.

The whole set of drying system adopts PLC programmable controller centralized control, independent research and development of drying

control program can automatically compensate heating power according to the ambient temperature, to ensure the stability of drying water,

can be set timing drying, constant temperature drying, constant humidity drying, etc., the system can automatically detect temperature,

material level, fault, etc., the operation panel adopts a large size color touch screen, can intuitively display the operating status, temperature,

fault, etc. of each equipment of the system.

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/707

https://www.facebook.com/flourmachinechina

https://www.linkedin.com/company/28728730/admin/feed/posts/

https://www.tumblr.com/blog/flourmillmachine

https://www.instagram.com/flourmachine/

https://www.blogger.com/u/0/blog/post/edit/4145872885004376169/3547941467734070561

https://youtu.be/JRE8WTfT1rU

A Dryer of flour,Germs,Bran of wheat and maize is an industrial drying system designed to reduce moisture content in by-products generated from grain milling, oil extraction, and feed mill processing. Proper drying is essential to prevent mold growth, microbial contamination, and nutrient degradation. In flour mills, the Dryer of flour,Germs,Bran of wheat and maize improves storage stability, while in oil and feed mills it enhances product safety, shelf life, and transport efficiency by ensuring consistent moisture control.

In grain processing plants, the Dryer of flour,Germs,Bran of wheat and maize operates by applying controlled heat and airflow to remove excess moisture from wheat bran, maize bran, and germs. The drying process is carefully regulated to protect protein, fiber, and oil content. By using indirect heating or low-temperature airflow, the Dryer of flour,Germs,Bran of wheat and maize ensures uniform drying without burning or nutrient loss, making it suitable for high-quality grain processing operations.

In oil mills, the Dryer of flour,Germs,Bran of wheat and maize is critical for stabilizing germs and bran before oil extraction or storage. High moisture levels can lead to enzymatic activity and rancidity, reducing oil yield and quality. The Dryer of flour,Germs,Bran of wheat and maize reduces moisture to optimal levels, improving oil extraction efficiency and preventing spoilage. This controlled drying also protects valuable oils and ensures consistent processing performance in oil milling systems.

Moisture control is the core function of a Dryer of flour,Germs,Bran of wheat and maize because excess moisture encourages bacteria, mold, and toxin formation. Precise drying ensures flour by-products remain safe for food, feed, or industrial use. The Dryer of flour,Germs,Bran of wheat and maize uses sensors, airflow management, and temperature control to achieve stable moisture levels, helping grain, oil, and feed mills comply with food safety and quality standards.

Feed mills rely on the Dryer of flour,Germs,Bran of wheat and maize to produce stable raw materials for animal feed formulations. Wet bran or germs can cause blockages, fermentation, and uneven mixing. By using a Dryer of flour,Germs,Bran of wheat and maize, feed mills achieve uniform dryness, improved pellet quality, and reduced energy loss during downstream processing. This results in better feed consistency, longer storage life, and reduced operational downtime.

A modern Dryer of flour,Germs,Bran of wheat and maize may use hot air circulation, indirect steam heating, or low-temperature belt drying technology. These systems are designed to handle light, fibrous materials like bran and oil-rich germs. The Dryer of flour,Germs,Bran of wheat and maize ensures even exposure to heat while minimizing dust generation and product loss, making it suitable for continuous industrial operation in grain, oil, and feed mills.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000