Heavy Duty Combined Cleaning Sifter Heavy Duty Combined Cleaning Screen applied to cleaning the grains like wheat,maize,rice,millet, sorghum,barley,all kind of oil seeds,various kind of beans,winery, brewing,pharmaceutical,oil and chemicals industries, also in grain storges, silo of up to 300,000 tons of vertical silo warehouse:www.immyhitech.com

Heavy Duty Combined Cleaning Sifter Heavy Duty Combined Cleaning Screen applied to cleaning the grains like wheat,maize,rice,millet, sorghum,barley,all kind of oil seeds,various kind of beans,winery, brewing,pharmaceutical,oil and chemicals industries, also in grain storges, silo of up to 300,000 tons of vertical silo warehouse: www.immyhitech.com

Heavy Duty Combined Cleaning (sifter) applied to cleaning the grains like wheat,maize,rice,millet, sorghum,barley,all kind of oil seeds,various kind of beans,winery,brewing,pharmaceutical and chemicals, also in grain storges, silo of up to 300,000 tons of vertical silo warehouse.

For any grain and other bulk processing plant, conditioning and cleaning are key steps.Its purpose is to extend the shelf life of food and improve product quality.

This step can prevent pests and diseases, optimize the processing flow and enhance product reliability.

Application field:

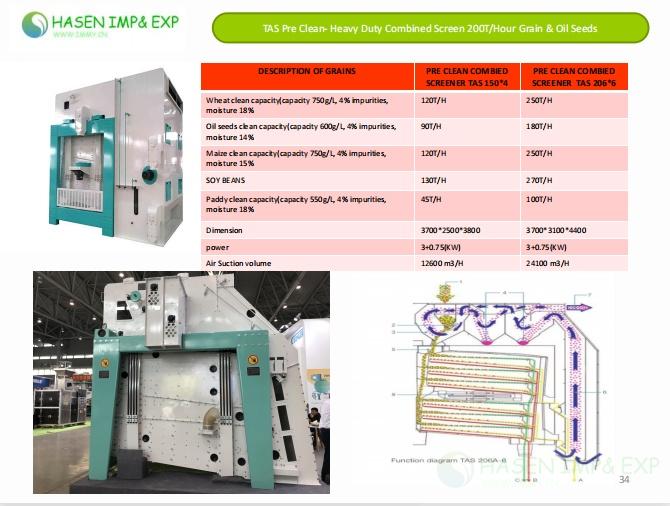

HEAVY DUTY COMBINED CLEANING SCREEN SIFTER is a high-end grain cleaning equipment, application and wheat, barley, rye, oats, corn, rice, soybean, high grain and other cereals secondary cleaning. Suitable for wharf grain storage and logistics, flour factory, rice factory, oil factory, grain depot, wine and other industries. Combined cleaning sieve combined with primary cleaning sieve will be the best solution for grain cleaning.

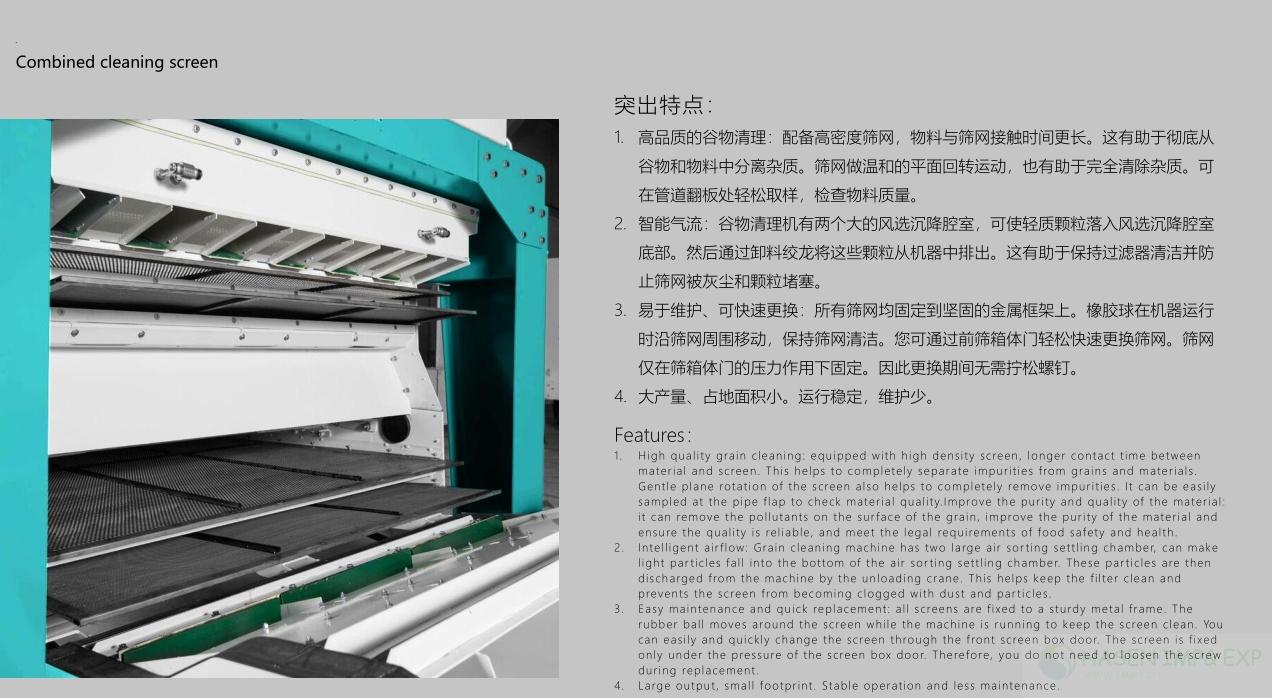

Features:

1.High quality grain cleaning: equipped with high density screen, longer contact time between material and screen. This helps to completely separate impurities from grains and materials. Gentle plane rotation of the screen also helps to completely remove impurities. It can be easily sampled at the pipe flap to check material quality Improve the purity and quality of the material: it can remove the pollutants on the surface of the grain, improve the purity of the material and ensure the quality is reliable, and meet the legal requirefients of food safety and health.

2. Intelligent airflow: Grain cleaning machine has two large air sorting settling chamber, can make light particles fall into the bottom of the air sorting settling chamber. These particles are then discharged from the machine by the unloading crane. This helps keep the filter clean and prevents the screen from becoming clogged with dust and particles.

3. Easy maintenance and quick replacement all screens are fixed to a sturdy metal frame. The rubber ball moves around the screen while the machine is running to keep the screen clean. You can easily and quickly change the screen through the front screen box door. The screen is fixed only under the pressure of the screen box door Therefore, you do not need to loosen the screw during replacement.

4. Large output, small footprint. Stable operation and less maintenance.

Optional equipment models include These devices are ideally suited for storing grain and bulk storage silos, harbors, flour, rice processing plants, seed processing plants and breweries.Safety devices such as vibration monitors on the screen box prevent system malfunctions.

· A large number of punched sieve plates in a compact space with proven flat

swivel technology ensure high throughput while requiring less space.

HEAVY DUTY COMBINED CLEANING SCREEN SIFTER applied to cleaning the grains like wheat,maize,rice,millet, sorghum,barley,all kind of oil seeds,various kind of beans,winery, brewing,pharmaceutical. oil seeds and chemicals,grain storges, silo of up to 300,000 tons of vertical silo warehouse.

https://youtube.com/shorts/_ev0xL6kqJY?feature=share

https://youtube.com/shorts/W3v4H_kYrhk

The Heavy Duty Combined Cleaning Sifter is an advanced material pre-cleaning and grading machine designed to remove impurities, foreign materials, and oversized or undersized particles from bulk raw materials. In grain, oil, and feed mills, the Heavy Duty Combined Cleaning Sifter plays a critical role in ensuring raw materials meet quality standards before storage, weighing, milling, or further processing. Its heavy-duty construction allows continuous operation in high-capacity environments such as grain storages, vertical silos, and industrial warehouses.

The Heavy Duty Combined Cleaning Sifter operates through a combination of vibration, screening layers, and airflow separation to clean grains efficiently. Raw material enters the Heavy Duty Combined Cleaning Sifter, where large impurities such as straw, stones, and husks are removed by top screens, while finer dust and sand are separated through lower sieves and aspiration systems. This multi-stage process ensures high cleaning efficiency while maintaining grain integrity.

The Heavy Duty Combined Cleaning Sifter is suitable for cleaning a wide range of grains including wheat, maize, rice, millet, sorghum, and barley. Due to adjustable screens and airflow, the Heavy Duty Combined Cleaning Sifter can be configured to match the size, weight, and cleanliness requirements of each grain type. This flexibility makes it ideal for multi-grain facilities and export-oriented grain terminals.

Yes, the Heavy Duty Combined Cleaning Sifter is widely used for cleaning all kinds of oilseeds such as soybean, sunflower seed, rapeseed, and groundnut, as well as various kinds of beans. The Heavy Duty Combined Cleaning Sifter effectively removes broken seeds, stones, metal fragments, and dust, helping oil mills and food processors protect downstream equipment and improve product yield.

In feed mills, the Heavy Duty Combined Cleaning Sifter ensures raw materials such as corn, wheat bran, soybean meal, and additives are free from contaminants before weighing and mixing. The Heavy Duty Combined Cleaning Sifter improves feed safety, protects pellet mills and grinders, and ensures consistent feed quality. Its heavy-duty design supports high throughput and continuous feed production lines.

The Heavy Duty Combined Cleaning Sifter is a key component in grain handling and weighing systems by stabilizing material flow before electronic scales or batching systems. By removing impurities and equalizing material size, the Heavy Duty Combined Cleaning Sifter enhances weighing accuracy and reduces scale errors. This makes it indispensable in automated grain terminals, oil processing plants, and feed batching systems.

The Heavy Duty Combined Cleaning Sifter is specifically designed for large-scale grain storages and silo systems, including vertical silo warehouses with capacities up to 300,000 tons. Installed at intake or discharge points, the Heavy Duty Combined Cleaning Sifter ensures incoming grain is clean before storage, reducing pest risk, improving aeration efficiency, and protecting silo structures from debris damage.

In brewery and winery operations, the Heavy Duty Combined Cleaning Sifter is used to clean barley, malt, and other raw materials before fermentation. The Heavy Duty Combined Cleaning Sifter removes dust, stones, and foreign particles that could negatively affect fermentation quality, taste consistency, and equipment hygiene, making it a critical pre-processing step in beverage production.

The Heavy Duty Combined Cleaning Sifter is also widely applied in pharmaceutical, oil, and chemical industries where raw material purity is essential. With precise screening and dust separation, the Heavy Duty Combined Cleaning Sifter helps meet strict quality and safety standards, supports contamination control, and ensures stable material flow for further processing or packaging.

The Heavy Duty Combined Cleaning Sifter features a reinforced steel frame, wear-resistant screens, high-efficiency vibration motors, and optimized airflow design. These features allow the Heavy Duty Combined Cleaning Sifter to operate reliably under heavy loads, harsh environments, and continuous production schedules, making it suitable for industrial-scale grain and material handling operations.

By integrating multiple cleaning functions into one unit, the Heavy Duty Combined Cleaning Sifter reduces the need for separate machines and lowers maintenance costs. The Heavy Duty Combined Cleaning Sifter increases throughput, reduces downtime, and improves overall plant efficiency, making it a cost-effective solution for grain, oil, and feed mill operators.

The Heavy Duty Combined Cleaning Sifter helps producers meet international quality standards by ensuring uniform cleanliness and impurity removal. Export-oriented facilities rely on the Heavy Duty Combined Cleaning Sifter to deliver consistent product quality, reduce rejection risks, and enhance brand reputation in global grain and oilseed markets.

The Heavy Duty Combined Cleaning Sifter can be customized with different screen sizes, airflow systems, capacities, and automation interfaces. This adaptability allows the Heavy Duty Combined Cleaning Sifter to serve diverse applications ranging from small feed mills to large integrated grain terminals and industrial processing plants.

If you are looking for reliable design, manufacturing, and technical support for a Heavy Duty Combined Cleaning Sifter, please contact WUXI HASEN for professional solutions, system integration, and customized services for your Heavy Duty Combined Cleaning Sifter.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000