Indented Cylinder Separator:www.immy.cn / www.immyhitech.com

Indented Cylinder Separator Fully Closed Drum Separator(Eye Choice)for all kind of grain oil seeds like rice,buckwheat and oat etc selection and separating.

This Separator is designed for separation treatment of leftover in the flour mill.

Classification of rice and treatment of brokent rice in the rice mill.

Selection of seeds in the seeds station.

Separation of stock in the beer factor and oat flake mill.

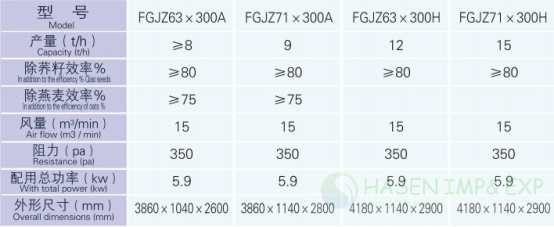

DETAIL SPECIFICATION:

An Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) is a high-precision grain separation machine designed to classify and separate agricultural materials based on length differences. It uses a rotating indented cylinder (also called “eye pockets”) to selectively lift and separate grains or oilseeds that differ slightly in size. The fully closed drum design ensures dust control, hygienic operation, and stable performance, making it ideal for modern grain processing plants.

This equipment is widely used in rice mills, oat processing lines, buckwheat cleaning systems, seed conditioning plants, and oilseed preparation facilities.

“Eye Choice” refers to the customizable indented pockets (eyes) inside the rotating cylinder. Different grains require different eye diameters and shapes. By selecting the appropriate eye size, the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) can precisely separate:

Broken rice from whole rice

Short grains from long grains

Weed seeds from edible grains

Oats from barley

Buckwheat kernels from impurities

This flexibility makes the Eye Choice system highly adaptable to multiple grain and oilseed types.

The Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) is suitable for a wide range of agricultural products, including but not limited to:

Rice (paddy rice, brown rice, white rice, broken rice)

Buckwheat

Oats

Wheat

Barley

Sorghum

Millet

Corn fragments

Sunflower seeds

Rapeseed

Soybeans (length grading applications)

Its ability to handle both grain and oilseeds makes it an essential machine in multi-crop processing facilities.

The working principle is simple yet highly effective:

Material enters the rotating indented cylinder.

Shorter grains fit into the indented eyes.

As the cylinder rotates, these grains are lifted.

Gravity causes them to fall into a collection trough.

Longer grains remain outside the eyes and exit separately.

Because the drum is fully closed, the process is protected from external contamination, and dust emission is minimized. This improves product purity, worker safety, and environmental compliance.

The Fully Closed Drum Separator design offers several important benefits:

Dust control: Reduces airborne particles and improves plant hygiene

Stable operation: Prevents material loss and external airflow interference

Noise reduction: Enclosed structure lowers operating noise

Food safety: Meets higher sanitation standards

Longer service life: Protects internal components from external damage

These advantages make the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) ideal for food-grade grain and oilseed processing.

Length-based separation is critical for improving final product quality. Even small differences in grain length can affect:

Milling efficiency

Packaging consistency

Market value

Consumer acceptance

For example, in rice processing, removing broken rice improves the grade of whole rice. In oats and buckwheat, length separation helps eliminate foreign seeds and impurities. The Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) is specifically designed to achieve this precision.

Yes. One of the key strengths of the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) is its modular eye selection system. By changing or adjusting the indented cylinder specifications, the same machine can process different grains and oilseeds efficiently. This reduces capital investment and increases operational flexibility.

Absolutely. This separator is designed for continuous, high-capacity industrial operation. It can be integrated into:

Grain cleaning lines

Rice milling plants

Seed processing systems

Oilseed preparation lines

The robust construction and precision engineering ensure stable performance over long operating hours.

The Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) improves product quality by:

Removing broken or undersized grains

Eliminating foreign seeds and impurities

Ensuring uniform grain length

Enhancing appearance and consistency

Higher purity and uniformity directly translate into higher market value and better downstream processing results.

Yes. Modern designs focus on user-friendly operation, including:

Simple adjustment of rotation speed

Easy access for cleaning and maintenance

Durable wear-resistant materials

Low energy consumption

Routine maintenance mainly involves cleaning and periodic inspection, making the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) cost-effective over its lifespan.

Unlike sieves or gravity separators, which rely on size or weight, the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) specializes in length separation. This makes it irreplaceable in applications where grains have similar widths and weights but differ in length. It is often used in combination with other separators to achieve optimal cleaning results.

Yes. The Eye Choice concept allows customization of:

Indent size

Cylinder length

Drum speed

Capacity

Material handling configuration

This ensures the separator meets specific requirements for rice, buckwheat, oats, and various oilseeds.

Industries that commonly use the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) include:

Rice milling industry

Grain trading and storage facilities

Seed processing companies

Oilseed crushing plants

Agricultural product exporters

Its versatility makes it a core machine in modern grain processing.

By improving separation accuracy and reducing waste, the Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) helps processors:

Reduce raw material loss

Increase yield

Lower energy consumption

Minimize dust emissions

This supports both economic and environmental sustainability.

Choosing a reliable manufacturer is essential for long-term performance, precision, and service support.

For professional solutions, technical support, and customized Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice) systems for rice, buckwheat, oats, and all kinds of grain and oil seeds, please contact with WUXI HASEN (www.immyhitech.com) Indented Cylinder Separator Fully Closed Drum Separator (Eye Choice).

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000