Twin Compartment check sifter-Double Bins Sifter(SFS) is utilized as a final check (security) sifter before wheat flour is sent to wheat flour storage or packing machine to ensure wheat bran particles or particles bigger that wheat flour particles are removed.

www.immyhitech.com

The machine for sifting

Twin Compartment check sifter-Double Bins Sifter-Twin Section Plansifter (SFS) is utilized as a final check (security) sifter before wheat flour is sent to wheat flour storage or packing machine to ensure wheat bran particles or particles bigger that wheat flour particles are removed.

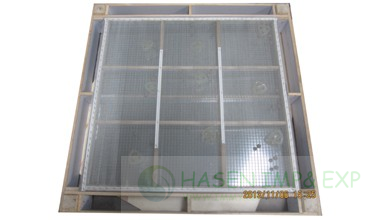

The twin-section plansifter is a kind of practical flour milling equipment. It is mainly used for the last sieving between the sifting by plansifter and the flour packing in the flour mills, as well as the classification of pulverulent materials, coarse wheat flour, and intermediate, grinded materials. Currently, it has been widely adopted in modern flour mills and rice grinding mills. We can provide different sieving designs for different sifting performance and different intermediate materials.

Working principle

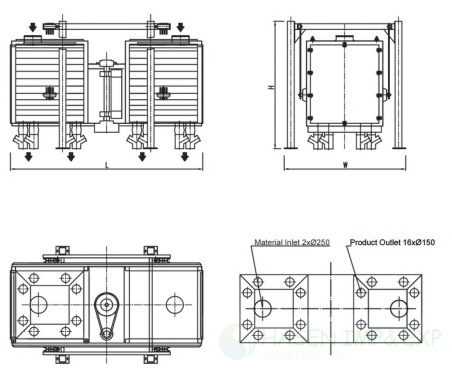

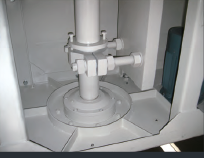

The Sifter is driven by a motor installed under the main frame to do plane rotary motion through the eccentric block. The material is fed into the inlet and flows down step by step according to respective design for different materials, and in the same time it is separated to several streams according to the particle size. The material can be separated into max. four types material. The flow sheet can be designed by different requirements.

Feature

1. The sieve frame size of the plansifter is available in 630×630mm, 700mm×700mm, 830mm×830mm, 100mm×100mm.

2. Modular design is introduced, so you can change the sieve frame quantity to get different sieving performance according to needs.

3. The adjustable counterweight is mounted with SKF (Sweden) bearings.

4. The sieve frames of the twin-section plansifter are made from imported wooden, and coated with plastic melamine lamination. They are demountable and interchangeable, and are equipped with stainless steel trays. Each whole section is clamped by a metal frame and pressure micrometric screws from the top. It is easy and quick to change the sifting scheme of the plansifter if necessary.

5. Our twin-section plansifter comes with two sections, so its production capacity is higher than that of the mono-section plansifter. It has small size, light weight, and only occupy a small place.

6. The sieves pack is suspended by its own frame which is installed on the floor or suspended by a separated frame fixed on the ceiling.

7. The SEFAR sieves are optional.

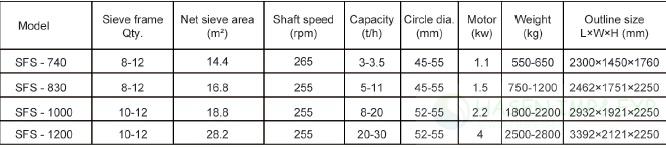

DETAIL SPECIFICATION OF DOUBLE BINS SIFTER

Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is utilized as a final check (security) sifter before wheat flour is sent to wheat flour storage or packing machine to ensure wheat bran particles or particles bigger that wheat flour particles are removed.

www.immyhitech.com

Double Bins Sifter Video

https://youtube.com/shorts/31m8Iga0qKo

https://youtube.com/shorts/Y0VGWhFjUCc

https://youtube.com/shorts/Y0VGWhFjUCc?feature=share

The Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is a critical security machine used at the final stage of wheat flour processing. It is installed before flour storage silos or packing machines to ensure that wheat bran particles, foreign contaminants, or oversized particles are completely removed. This final screening step protects flour purity, meets food safety regulations, and prevents customer complaints. The twin compartment design allows simultaneous and efficient screening, ensuring uninterrupted flour flow while maintaining consistent quality standards demanded by modern milling operations worldwide. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

The Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) operates by passing flour through precisely engineered sieve frames that separate fine flour from unwanted coarse particles. Flour enters two independent compartments, allowing continuous operation even during maintenance. The machine uses vibration and centrifugal force to ensure effective screening without damaging flour quality. This reliable working principle makes it ideal as a final check sifter, guaranteeing that only clean, safe, and uniform wheat flour reaches storage or packaging lines in high-capacity milling plants. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

A major advantage of the Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is operational continuity. One compartment can remain active while the other is inspected or cleaned, reducing downtime and improving production efficiency. This design also increases screening accuracy and allows flexible capacity management. For mills aiming to optimize productivity while maintaining strict quality control, the twin compartment structure offers superior performance compared to single-bin sifters commonly used in older flour milling systems. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

The Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is typically installed as the last security sifter after flour blending and before flour storage bins or packing machines. Its role is to catch any remaining impurities that may have passed through upstream processes. Installation at this point ensures maximum food safety compliance and protects downstream equipment. This strategic positioning is essential for flour mills exporting premium wheat flour to global markets with strict hygiene and quality requirements. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

The Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is designed to remove wheat bran flakes, fiber particles, insects, and other oversized contaminants that may compromise flour quality. By using fine mesh sieves customized to flour specifications, it ensures consistent particle size distribution. This makes the final product suitable for bakeries, food processors, and consumers who demand smooth texture and high purity wheat flour in every batch. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

Yes, the Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is engineered for medium to large-scale flour milling operations. Its robust construction, balanced vibration system, and twin-section configuration allow it to handle high throughput without sacrificing screening efficiency. The machine supports continuous operation, making it ideal for modern automated flour mills seeking reliability, reduced maintenance time, and consistent product quality at high production volumes. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

Food safety is a primary concern in milling, and the Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) plays a vital role in meeting international standards. By acting as a final inspection point, it minimizes the risk of foreign matter reaching packaged flour. Its hygienic design, easy-to-clean surfaces, and secure sealing help mills comply with HACCP, ISO, and other food safety regulations demanded by global wheat flour markets. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

Routine maintenance of the Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) includes periodic sieve inspection, cleaning, and checking vibration components. The twin compartment layout simplifies maintenance by allowing one section to be serviced while the other continues operating. This reduces production losses and extends machine lifespan. With proper preventive maintenance, the check sifter delivers long-term stable performance in demanding flour milling environments. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

The Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS) is the ideal solution for mills prioritizing quality, safety, and efficiency. Its proven design ensures clean flour output, reduced downtime, and compliance with global standards. As flour consumers become more quality-conscious, investing in a reliable final check sifter strengthens brand reputation and operational confidence. This makes it an essential component of any advanced wheat flour milling system. Please contact with WUXI HASEN For Twin Compartment check sifter-Double Bins Sifter Twin Section Plansifter (SFS)

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000