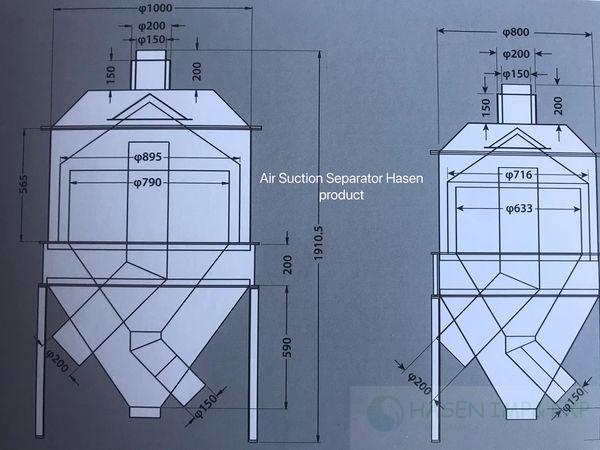

Air Suction Separator to absorb air from grain in separation of husk and other low specific gravity impurities in wheat and maize flour milling processing line.www.immyhitech.com

It is to absorb air from grain in separation of husk and other low specific gravity impurities in wheat and maize flour milling processing line.

Air Suction Separator is to absorb air from grain in separation of husk and other low specific gravity impurities in wheat and maize flour milling processing line.We provide integrated grain and oil engineering equipment EPC turnkey project 100TPD to 3000TPD.

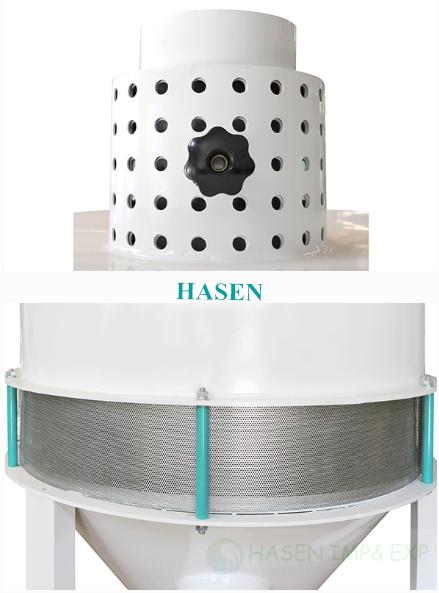

Its biggest characteristic: suction area is large, save wind, air selection effect is good.

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/623

https://www.blogger.com/u/0/blog/posts/4145872885004376169

https://www.linkedin.com/in/grainmachinecn/

https://www.facebook.com/Flourmachines/

An Air Suction Separator is a critical cleaning and separation machine used in wheat and maize flour milling processing lines to remove husk, dust, chaff, straw, and other low specific gravity impurities from grain. The Air Suction Separator works by using controlled airflow to separate lighter impurities from heavier grain kernels before grinding, ensuring cleaner raw material and higher flour quality.

The Air Suction Separator plays an essential role in protecting downstream milling equipment and improving final flour quality. By removing lightweight impurities early in the process, the Air Suction Separator reduces wear on rollers, sifters, and purifiers while ensuring consistent milling performance in wheat and maize flour milling processing lines.

The Air Suction Separator functions on the principle of aerodynamic separation, where grain is exposed to an adjustable air stream. In this process, heavier wheat or maize kernels fall naturally due to gravity, while lighter impurities are lifted and extracted through suction ducts. This controlled airflow allows the Air Suction Separator to achieve high separation efficiency without damaging the grain.

An Air Suction Separator is designed to remove husk, dust, straw, chaff, broken leaves, empty grains, and other low-density contaminants. In wheat and maize flour milling, the Air Suction Separator is especially effective at removing materials that cannot be separated efficiently by screens or mechanical sieves alone.

The Air Suction Separator is typically installed at the grain intake or pre-cleaning stage of wheat and maize flour milling processing lines. In some advanced milling systems, the Air Suction Separator may also be used after scourers or before conditioning to ensure maximum cleanliness before grinding.

By removing light impurities and husk efficiently, the Air Suction Separator helps maintain uniform grain quality entering the milling section. This results in improved flour color, reduced ash content, and better baking performance, making the Air Suction Separator a key quality-control component in modern flour mills.

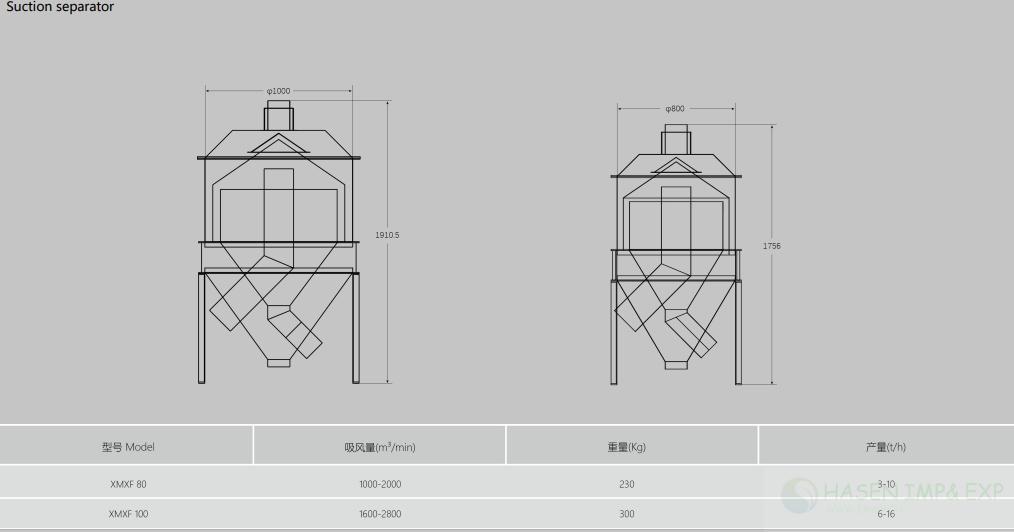

Yes, a properly designed Air Suction Separator can process both wheat and maize effectively. The airflow and suction parameters of the Air Suction Separator can be adjusted to suit different grain sizes and densities, making it a versatile solution for multi-grain flour milling processing lines.

An Air Suction Separator typically consists of a feeding inlet, separation chamber, adjustable air control system, suction fan, and impurity discharge outlet. Each component of the Air Suction Separator is engineered to ensure stable airflow, precise separation, and minimal grain loss during operation.

Airflow in an Air Suction Separator is regulated through adjustable dampers, suction fans, and air channels. Proper airflow adjustment is crucial for achieving optimal separation efficiency, as too much suction may cause grain loss, while insufficient airflow may reduce impurity removal performance.

Compared to mechanical cleaners, the Air Suction Separator offers superior efficiency in removing lightweight impurities. The Air Suction Separator operates continuously, requires less maintenance, and provides more precise separation, making it ideal for modern wheat and maize flour milling processing lines focused on high productivity.

A well-designed Air Suction Separator optimizes airflow to achieve high separation efficiency with minimal energy usage. By reducing unnecessary mechanical processing and preventing equipment damage, the Air Suction Separator indirectly lowers overall energy and maintenance costs in flour milling operations.

The Air Suction Separator prevents foreign matter from entering sensitive milling machines such as roller mills and sifters. By eliminating lightweight debris early, the Air Suction Separator extends equipment lifespan, reduces downtime, and improves overall system reliability.

Maintenance of an Air Suction Separator is relatively simple, involving regular inspection of airflow channels, suction fans, and discharge outlets. With proper operation and routine cleaning, the Air Suction Separator delivers long-term stable performance in wheat and maize flour milling plants.

Modern Air Suction Separator systems can be customized based on plant capacity, grain type, and processing requirements. Adjustable airflow design, modular construction, and automation options allow the Air Suction Separator to integrate seamlessly into existing flour milling processing lines.

When choosing an Air Suction Separator, factors such as capacity, separation efficiency, airflow control accuracy, and build quality should be considered. Selecting the right Air Suction Separator ensures optimal impurity removal and consistent milling performance for wheat and maize processing.

The Air Suction Separator contributes to food safety by removing contaminants that may carry dust, microorganisms, or foreign particles. Clean raw material entering the milling section helps flour producers comply with international food safety and hygiene standards.

In modern high-capacity flour mills, the Air Suction Separator is indispensable for achieving consistent quality, operational efficiency, and equipment protection. The Air Suction Separator supports automation, reduces manual intervention, and ensures stable production output.

By delivering cleaner grain to downstream processes, the Air Suction Separator improves grinding efficiency, reduces reprocessing, and stabilizes flour yield. This makes the Air Suction Separator a vital component for optimizing the entire wheat and maize flour milling processing line.

The Air Suction Separator is designed for continuous, high-throughput operation in industrial flour mills. Its robust construction and reliable airflow system allow the Air Suction Separator to operate 24/7 with minimal performance variation.

For expert guidance, high-quality manufacturing, and reliable technical support, choosing a trusted supplier for your Air Suction Separator is essential to ensure long-term milling success. Please contact with WUXI HASEN For Air Suction Separator.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000