Corn Degerminator Machine with Vertical Intelligent Rube

Corn Degermination Machine with Vertical Intelligent Rube

feed mill, and the ideal equipment for maize de-embryo. ( www.immyhitech.com)

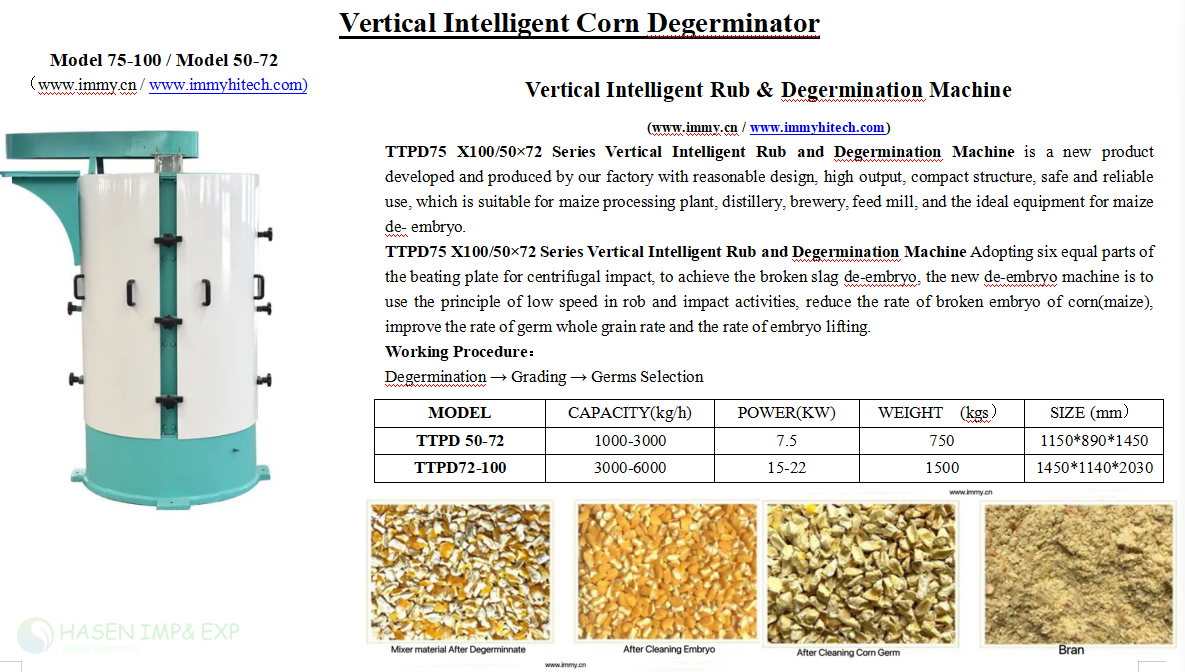

TTPD75 X100/50×72 Series Vertical Intelligent Rub and Degermination Machine Adopting six equal parts of the beating plate for centrifugal

impact, to achieve the broken slag de-embryo, the new de-embryo machine is to use the principle of low speed in rob and impact activities,

reduce the rate of broken embryo of corn(maize), improve the rate of germ whole grain rate and the rate of embryo lifting.

Working Procedure:

Degermination → Grading → Germs Selection

Detail Specification of Corn Degermination Machine with Vertical Intelligent Rube

A Maize (Corn) Degerminator is a specialized grain processing machine designed to efficiently remove the maize germ (embryo) from the endosperm while keeping the starch-rich portion intact. The Maize (Corn) Degerminator plays a critical role in maize dry milling, as the germ contains oil and enzymes that can negatively affect storage stability, flour quality, and fermentation performance if not properly separated.

In modern maize processing plants, a Maize (Corn) Degerminator is essential for improving product purity, increasing shelf life, and enhancing downstream processing efficiency. By removing the germ early in the process, the Maize (Corn) Degerminator helps reduce fat content, minimizes rancidity, and ensures more consistent milling, which is especially important for food, industrial, and feed applications.

The Maize (Corn) Degerminator works by applying controlled mechanical impact and friction to conditioned maize kernels. As the maize enters the Maize (Corn) Degerminator, rotating beaters or impellers strike the kernels, loosening the germ from the endosperm. The difference in density and structure allows the Maize (Corn) Degerminator to separate the germ efficiently while maintaining high starch recovery.

Proper maize conditioning is crucial for the optimal performance of a Maize (Corn) Degerminator. By adjusting moisture content before processing, the Maize (Corn) Degerminator can more easily loosen the germ without excessive breakage of the endosperm. Correct conditioning improves separation efficiency, reduces fines, and ensures stable operation of the Maize (Corn) Degerminator.

In distilleries, a Maize (Corn) Degerminator significantly improves alcohol yield and fermentation consistency. By removing the oil-rich germ, the Maize (Corn) Degerminator reduces inhibitors that can negatively affect yeast performance. This leads to cleaner fermentation, higher starch availability, and improved efficiency in ethanol and spirits production.

Breweries rely on a Maize (Corn) Degerminator to produce high-quality maize grits with low fat content. The Maize (Corn) Degerminator ensures uniform particle size and consistent starch quality, which is essential for stable mashing and predictable brewing results. Using a Maize (Corn) Degerminator also helps prevent off-flavors caused by maize oil oxidation.

In feed mills, a Maize (Corn) Degerminator allows producers to tailor nutritional profiles. The Maize (Corn) Degerminator separates germ, which can be processed into valuable by-products like maize oil or high-energy feed ingredients. This improves feed formulation flexibility and maximizes the economic value of maize processing using a Maize (Corn) Degerminator.

A typical Maize (Corn) Degerminator consists of a feeding system, a high-speed rotor, impact liners, and a discharge and separation system. Each component of the Maize (Corn) Degerminator is engineered to ensure efficient impact, controlled abrasion, and precise separation of germ and endosperm, resulting in reliable and repeatable processing performance.

By effectively removing the germ, a Maize (Corn) Degerminator produces starch with lower oil content and higher purity. The Maize (Corn) Degerminator ensures minimal contamination of starch with fat and enzymes, which is vital for food-grade flour, brewing adjuncts, and industrial starch applications that demand consistent quality.

Modern designs of the Maize (Corn) Degerminator focus on optimized rotor geometry and impact force to reduce unnecessary power consumption. A well-designed Maize (Corn) Degerminator achieves high degermination efficiency with lower energy input, helping processing plants reduce operating costs while maintaining high throughput.

A Maize (Corn) Degerminator minimizes kernel breakage and excessive fines by applying controlled mechanical action. This precision allows the Maize (Corn) Degerminator to protect the endosperm while separating the germ, resulting in higher product yield, less waste, and improved overall process economics.

Yes, a Maize (Corn) Degerminator is designed for continuous, large-scale operation in industrial maize processing plants. With robust construction and adjustable settings, the Maize (Corn) Degerminator can handle high capacities while maintaining stable performance across long production cycles.

The germ separated by a Maize (Corn) Degerminator is a valuable by-product rich in oil and nutrients. The Maize (Corn) Degerminator enables efficient recovery of this germ, which can be further processed into maize oil or high-value feed ingredients, increasing overall plant profitability.

Routine inspection and timely replacement of wear parts ensure long service life for a Maize (Corn) Degerminator. Regular maintenance of the rotor, liners, and bearings helps the Maize (Corn) Degerminator maintain consistent performance, reduce downtime, and ensure safe operation.

For detailed specifications, technical support, and professional solutions, manufacturers such as those featured at www.immyhitech.com provide comprehensive information about the Maize (Corn) Degerminator. For expert guidance, customized equipment, and reliable service, please contact with WUXI HASEN For Maize (Corn) Degerminator.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000