Bran Finisher is used in flour mill, maize (corn) flour mill, coarse grain flour making, feed factory, it can also screen beer pollen for hops processing We provide full solution of grain and oil engineering equipment with EPC turnkey project supplier.www.immyhitech.com

Bran Finisher

Bran Finisher is used in flour mill, corn flour mill, coarse grain flour making, feed factory, it can also screen beer pollen for hops processing We provide full solution of grain and oil engneering equipment with EPC turnkey project supplier. www.immy.cn /www.immyhitech.com

BRAN FINISHER machine is used in flour mill, corn flour mill, coarse grain flour making, feed factory,

it can also screen beer pollen for hops processing We provide full solution of grain and oil engneering equipment with EPC turnkey project supplier

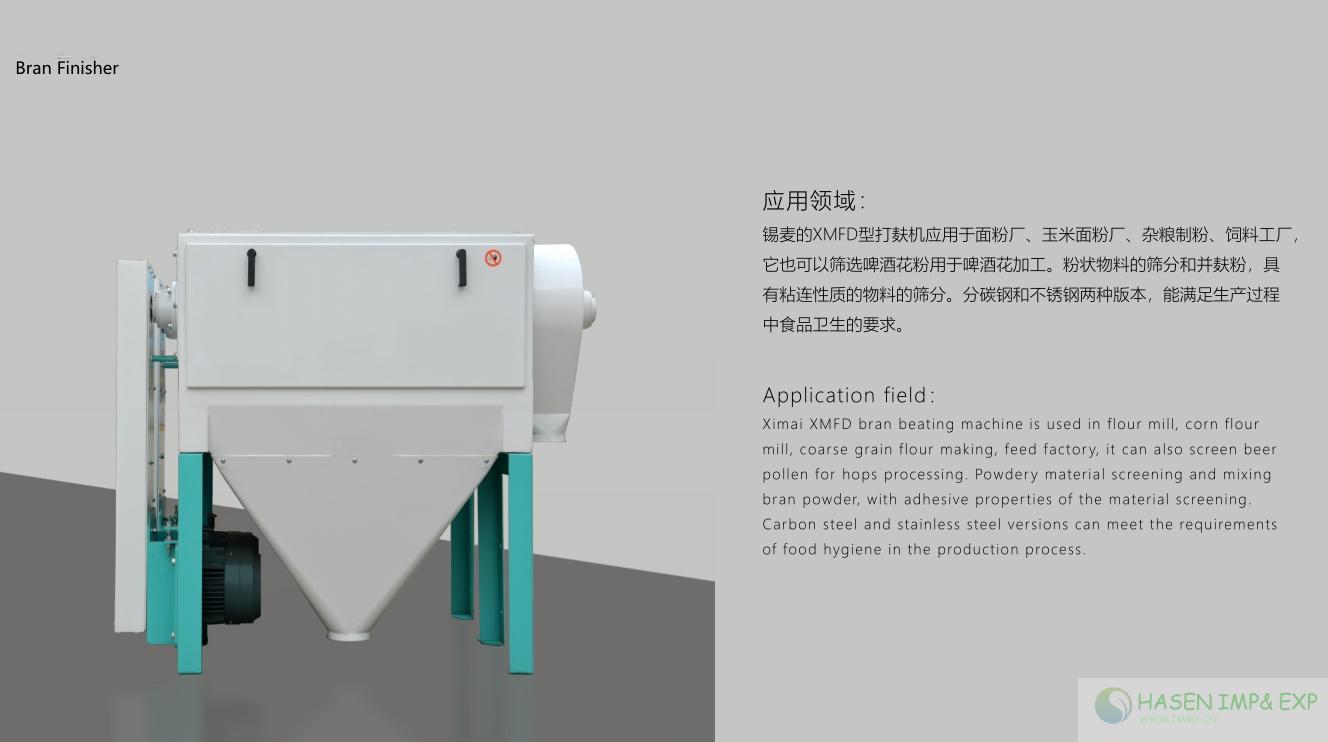

Application field:

BRAN FINISHER machine is used in flour mill,Maize corn flour mill, coarse grain flour making,feed factory, it can also screen

beer pollen for hops processing. Powdery material screening and mixing bran powder, with adhesive properties of the material screening.

Carbon steel and stainless steel versions can meet the requirements of food hygiene in the production process.

![]()

A Bran Finisher is a critical machine used in modern flour milling and grain processing plants to recover fine endosperm particles from bran after milling, and the WUXI HAEN Bran Finisher plays an essential role in improving flour yield and profitability. By applying controlled impact, rubbing, and screening actions, this equipment separates residual flour from bran without damaging fiber structure. The WUXI HAEN Bran Finisher is widely used in wheat flour mills, maize (corn) flour mills, coarse grain processing lines, feed factories, and even for special screening tasks such as beer pollen in hops processing. Its importance lies in maximizing extraction rates, reducing waste, and enhancing overall process efficiency within integrated grain and oil engineering systems.

The working principle of a Bran Finisher relies on mechanical friction, centrifugal force, and precise screening, and the WUXI HAEN Bran Finisher is designed to optimize these actions for consistent performance. Bran material enters the machine and is accelerated by a rotor, causing bran particles to rub against each other and against the screen surface. This action releases attached flour particles, which pass through the screen as fine flour, while cleaned bran exits separately. In a wheat or maize flour mill, the WUXI HAEN Bran Finisher is typically installed after break and reduction systems, ensuring maximum flour recovery while maintaining flour quality and stable ash content.

A high-quality Bran Finisher is versatile across multiple raw materials, and the WUXI HAEN Bran Finisher is engineered for wheat bran, maize bran, corn husk, and other coarse grain by-products. In maize (corn) flour mills, it efficiently separates fine corn flour from bran flakes, improving yield and uniformity. In coarse grain flour making, such as sorghum or barley, the WUXI HAEN Bran Finisher helps recover valuable fine particles that would otherwise be lost. Additionally, in feed factories, it prepares bran to a cleaner and more uniform state, making it suitable for pelletizing or direct feed use.

Yes, beyond flour mills, a Bran Finisher has specialized applications, and the WUXI HAEN Bran Finisher is also suitable for screening beer pollen in hops processing. In brewing-related industries, accurate separation of pollen or fine plant particles is essential for product consistency, and the controlled screening action of the WUXI HAEN Bran Finisher makes it adaptable for this task. Its adjustable rotor speed and interchangeable screens allow processors to fine-tune separation efficiency for non-traditional materials. This flexibility demonstrates why Bran Finisher equipment is increasingly used across food, feed, and agro-processing industries.

Improving flour yield directly impacts plant profitability, and the WUXI HAEN Bran Finisher is designed to maximize extraction without compromising quality. By recovering flour that remains attached to bran after milling, it reduces overall raw material loss and increases the total flour output per ton of grain. This recovered flour often has acceptable ash and color values, making it suitable for blending. The WUXI HAEN Bran Finisher also stabilizes downstream processes by delivering cleaner bran, reducing load on pneumatic conveying and storage systems, and lowering maintenance costs across the production line.

In feed factories, bran quality and consistency are crucial, and the WUXI HAEN Bran Finisher ensures bran is free from excess flour dust and fine impurities. Cleaned bran improves feed formulation accuracy, pellet durability, and nutritional consistency. By removing excess fines, the WUXI HAEN Bran Finisher also reduces dust generation, improving plant hygiene and worker safety. For integrated grain processing plants that combine flour milling and feed production, this machine serves as a key link between food-grade and feed-grade operations, maximizing value from every stage of grain processing.

In an EPC turnkey project, equipment integration and process optimization are critical, and the WUXI HAEN Bran Finisher is engineered to fit seamlessly into complete grain and oil engineering solutions. As a full-solution supplier, systems available via www.immyhitech.com include process design, equipment manufacturing, installation, and commissioning. The WUXI HAEN Bran Finisher is matched with upstream milling systems and downstream conveying and packaging equipment to ensure smooth operation. Proper integration ensures energy efficiency, stable throughput, and long-term reliability in both new plants and modernization projects.

Ease of maintenance is essential for continuous production, and the WUXI HAEN Bran Finisher is designed with durable components, easy-access covers, and replaceable screens. Routine maintenance involves inspecting the rotor, screens, and bearings, which can be done quickly to minimize downtime. The WUXI HAEN Bran Finisher offers stable operation with low vibration and noise, contributing to a safer and more efficient working environment. Its robust design ensures long service life even under high-capacity, continuous-duty conditions commonly found in industrial flour mills and feed plants.

Choosing the right Bran Finisher determines both product quality and operational efficiency, and the WUXI HAEN Bran Finisher stands out for its proven performance across flour milling, maize processing, coarse grain flour making, feed production, and hops pollen screening. With strong engineering support, customizable configurations, and compatibility with EPC turnkey solutions, it delivers reliable results in diverse applications. The WUXI HAEN Bran Finisher reflects a commitment to maximizing yield, reducing waste, and supporting sustainable grain processing, and please contact with WUXI HASEN For Bran Finisher.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000