Double Shaft Dampener Used to equalizing water during wheat maize millet etc such grain processing line.www.immyhitech.com

DOUBLE SHAFT DAMPENER( MOISTURE) MACHINE TO CONTROL MOISTURE IN WHEAT MAIZE MILLET PRODUCTION LINE Is used to equalizing water during grain processing line-We provide integrated grain and oil engineering equipment EPC turnkey project from CHina.

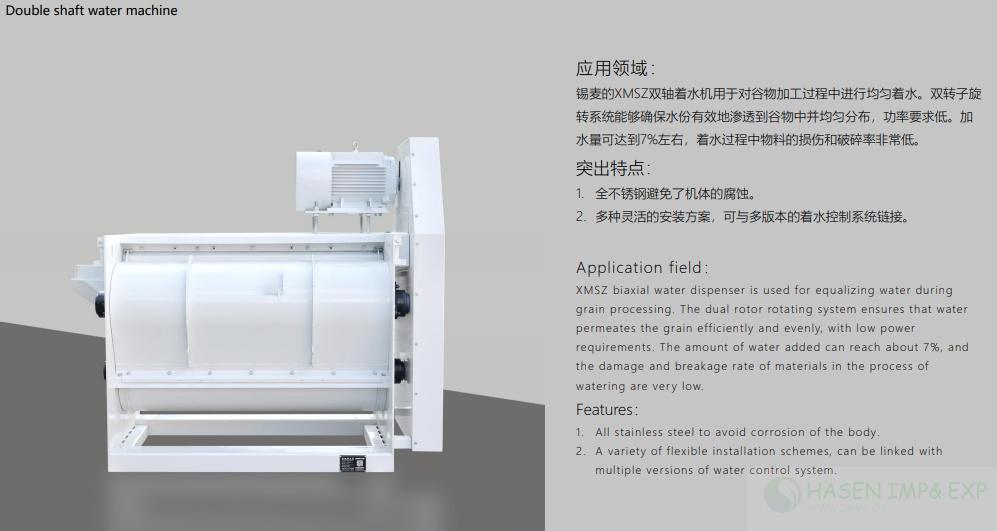

Application field:

DOUBLE SHAFT DAMPENER( MOISTURE) MACHINE TO CONTROL MOISTURE IN WHEAT MAIZE MILLET PRODUCTION LINE water dispenser is used for equalizing water during. grain processing. The dual rotor rotating system ensures that water

permeates the grain efficiently and evenly, with low power requirements. The amount of water added can reach about 7%, and the damage and breakage rate of

materials in the process of watering are very low.

DOUBLE SHAFT DAMPENER( MOISTURE) MACHINE TO CONTROL MOISTURE IN WHEAT MAIZE MILLET PRODUCTION LINE

Features:

1.All stainless steel to avoid corrosion of the body.

2.A variety of flexible installation schemes, can be linked with multiple versions of water control system.

Personalized selection:

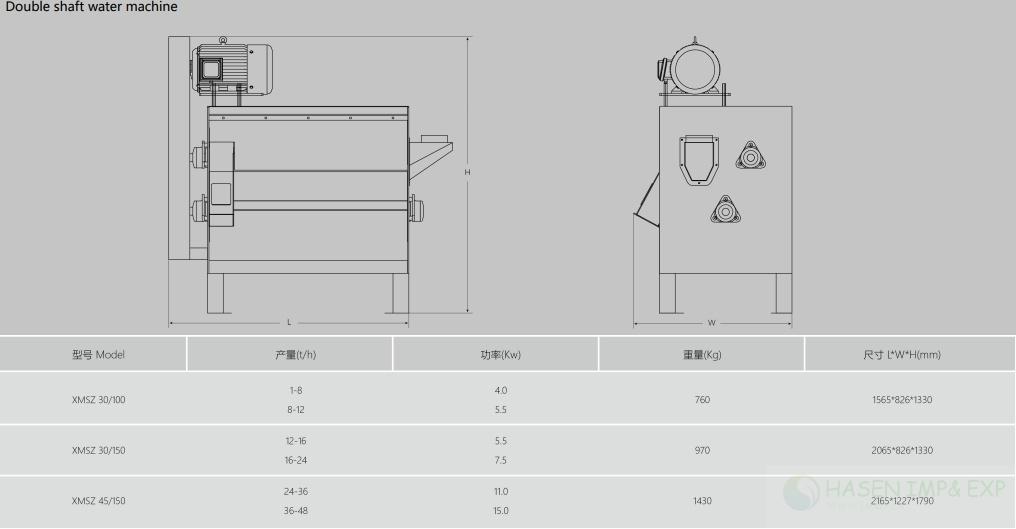

DOUBLE SHAFT MOISTURE MACHINE type rotary vibration shaker has 3 models; 30/100, 30/150, 45/150.

You can choose different models flexibly according to different process and capacity.

Application:

DOUBLE SHAFT MOISTURE MACHINE double shaft water machine is applied in 1500t/ 24H -3000t/24h powder making workshop and runs stably and reliably.

For more information please visit:

https://wordpress.com/post/wheatflourmill0.wordpress.com/586

https://www.facebook.com/maizemachinehasen

https://www.linkedin.com/company/28728730/admin/feed/posts

https://www.linkedin.com/feed/update/urn:li:share:7087284096241963010

https://www.blogger.com/u/0/blog/post/edit/4145872885004376169/1325553232452763988

Tumblr URL: www.tumblr.com/flourmillmachine

A Double Shaft Dampener is a critical conditioning machine used in modern wheat, maize, millet, and grain processing lines to evenly distribute and equalize water content before milling. The Double Shaft Dampener works by using two synchronized shafts with paddles that mix grain thoroughly while water is precisely added. This uniform hydration improves milling efficiency, reduces energy consumption, and enhances flour quality. In high-capacity processing lines, the Double Shaft Dampener ensures stable and repeatable conditioning results across different grain types. Please contact with WUXI HASEN For Double Shaft Dampener.

During wheat processing, the Double Shaft Dampener functions by intensively mixing wheat kernels while spraying controlled amounts of water onto the grain surface. The counter-rotating shafts in the Double Shaft Dampener create a rolling and folding action, ensuring each kernel absorbs moisture evenly. This process toughens bran and softens endosperm, which improves separation during milling. Proper conditioning through a Double Shaft Dampener directly affects flour extraction rate and quality consistency. Please contact with WUXI HASEN For Double Shaft Dampener.

A Double Shaft Dampener is especially important for maize and millet processing because these grains have harder structures and uneven moisture absorption characteristics. The Double Shaft Dampener ensures water penetrates the grain uniformly, reducing breakage and powdering during downstream grinding. By equalizing moisture, the Double Shaft Dampener improves yield, reduces dust, and stabilizes particle size distribution. For multi-grain processing plants, the Double Shaft Dampener offers flexible and reliable conditioning performance. Please contact with WUXI HASEN For Double Shaft Dampener.

Uniform water distribution is achieved in a Double Shaft Dampener through its dual-shaft design and optimized paddle configuration. The Double Shaft Dampener continuously lifts, turns, and disperses grain while water nozzles spray a fine mist across the full cross-section. This mechanical action prevents water accumulation or dry zones. As a result, the Double Shaft Dampener guarantees precise moisture control, which is essential for consistent grain quality before tempering or milling. Please contact with WUXI HASEN For Double Shaft Dampener.

Before tempering, the Double Shaft Dampener acts as the primary moisture equalization unit in the processing line. The Double Shaft Dampener prepares grain by ensuring initial water addition is evenly mixed, allowing tempering bins to work more efficiently. Without a Double Shaft Dampener, uneven hydration may occur, leading to inconsistent milling behavior. Therefore, the Double Shaft Dampener is a key link between cleaning and tempering stages. Please contact with WUXI HASEN For Double Shaft Dampener.

A Double Shaft Dampener improves milling efficiency by conditioning grain to the optimal moisture level required for smooth grinding. The Double Shaft Dampener reduces excessive bran breakage and lowers flour ash content. By stabilizing moisture distribution, the Double Shaft Dampener minimizes roller wear and energy usage. Milling lines equipped with a Double Shaft Dampener achieve higher throughput and more predictable performance, making it a cost-effective investment. Please contact with WUXI HASEN For Double Shaft Dampener.

Yes, a Double Shaft Dampener is designed to handle a wide range of capacities and grain types. Whether processing wheat, maize, millet, or blended grains, the Double Shaft Dampener can be adjusted for flow rate, water addition, and mixing intensity. Its robust mechanical structure ensures stable operation under continuous load. This adaptability makes the Double Shaft Dampener suitable for both medium and large-scale grain processing plants. Please contact with WUXI HASEN For Double Shaft Dampener.

A Double Shaft Dampener is typically manufactured using food-grade materials and smooth internal surfaces to prevent residue buildup. The Double Shaft Dampener supports easy cleaning and inspection, reducing the risk of contamination. Proper water atomization inside the Double Shaft Dampener avoids over-wetting, which could otherwise encourage microbial growth. These hygienic features make the Double Shaft Dampener ideal for modern food safety standards. Please contact with WUXI HASEN For Double Shaft Dampener.

Automation significantly enhances the accuracy and reliability of a Double Shaft Dampener. Sensors and control systems allow the Double Shaft Dampener to adjust water flow in real time based on grain input and moisture targets. This ensures consistent results even with variable raw material conditions. An automated Double Shaft Dampener reduces operator error and improves overall processing stability. Please contact with WUXI HASEN For Double Shaft Dampener.

Routine maintenance of a Double Shaft Dampener includes checking shaft alignment, paddle wear, bearings, and water nozzles. The Double Shaft Dampener is engineered for durability, but regular inspection ensures long service life and stable performance. Proper lubrication and cleaning keep the Double Shaft Dampener operating efficiently and prevent downtime in the grain processing line. Please contact with WUXI HASEN For Double Shaft Dampener.

Final product quality is strongly influenced by the conditioning stage, where the Double Shaft Dampener plays a central role. By equalizing moisture across all grains, the Double Shaft Dampener ensures uniform grinding behavior and consistent flour or meal characteristics. This leads to better color, texture, and processing performance for end users. The Double Shaft Dampener is therefore essential for high-quality grain products. Please contact with WUXI HASEN For Double Shaft Dampener.

Choosing a professional supplier ensures that the Double Shaft Dampener is properly designed, manufactured, and supported for long-term operation. A high-quality Double Shaft Dampener offers precise water control, reliable mixing, and strong structural performance. Professional technical support also ensures smooth integration into existing processing lines. For dependable solutions and expert service, please contact with WUXI HASEN For Double Shaft Dampener.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000