Friction Wheat Scourer for wheat cleaning in Wheat Maize Flour Milling Production Line- We provide integrated grain and Oil Engineering equipment EPC turnkey project from 100 TPD to 5000TPD Large sized milling lines.www.immyhitech.com

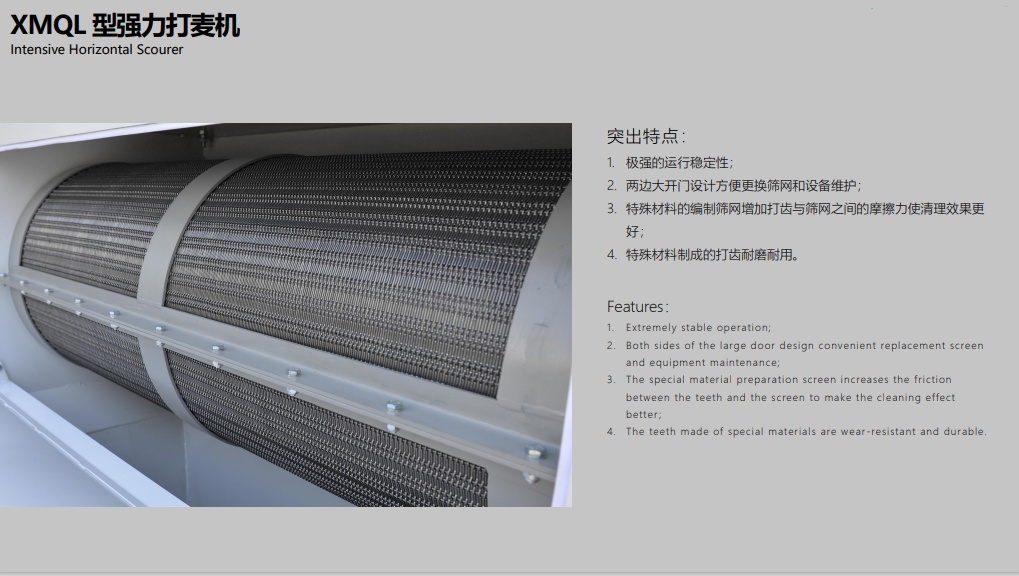

Friction Wheat Scourer

Friction Wheat Scourer for wheat cleaning in Wheat Maize Flour Milling Production Line- We provide integrated grain and Oil Engineering equipment EPC turnkey project from 100 TPD to 5000TPD Large sized milling lines. www.immyhitech.com

Friction Wheat Scourer for wheat cleaning in Wheat Maize Flour Milling Production Line

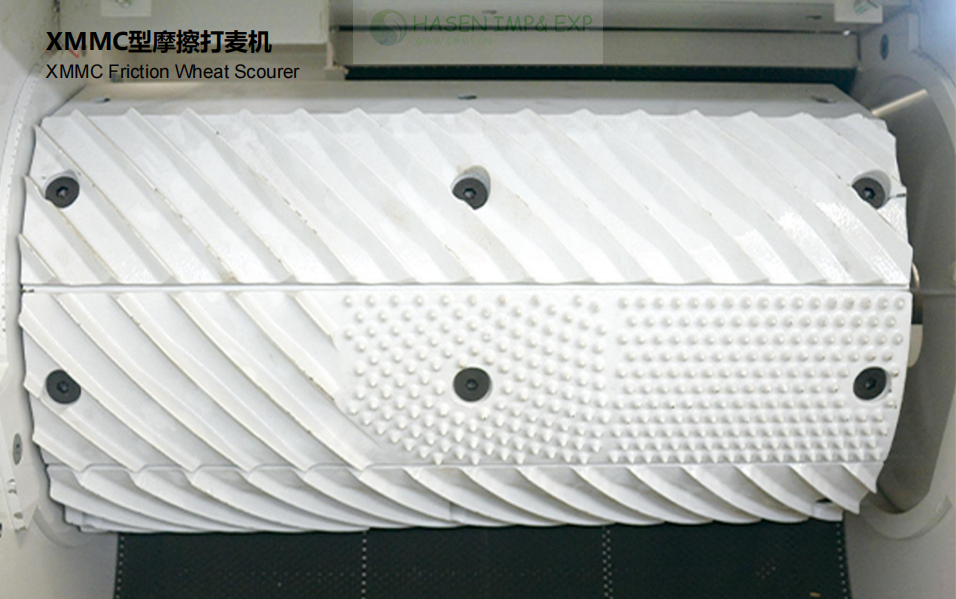

There are two models of the all-series friction

wheat scourer, the 30/60 friction wheat

scourer and the 45/80 friction wheat scourer.

Depending on the process and capacity, you can

flexibly choose different models.

Application field

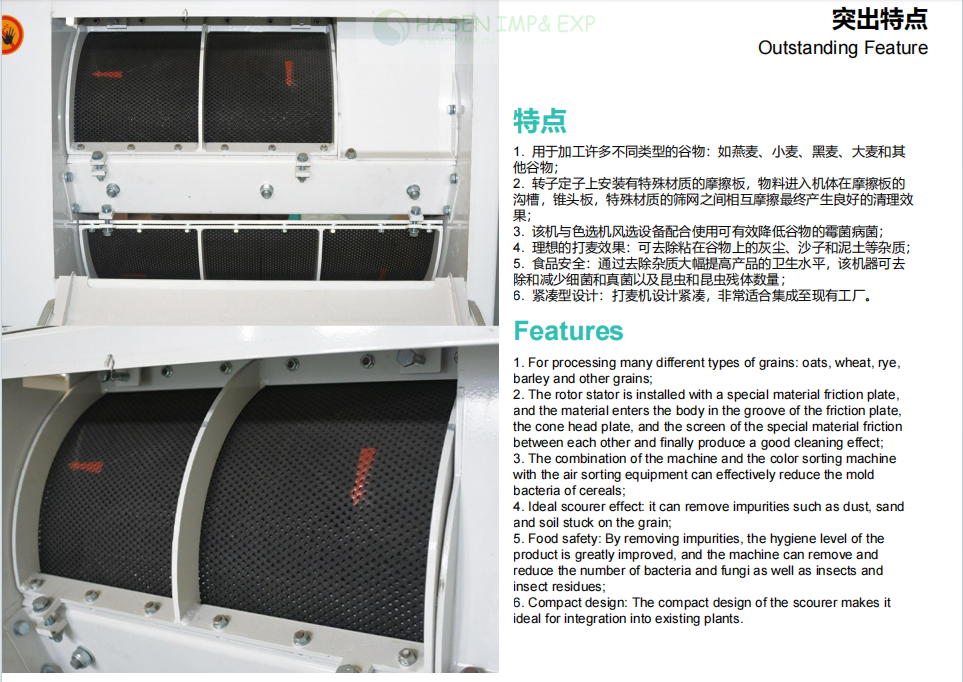

The Rob Scourer is used for cleaning wheat, barley, oats, rye, durum wheat, and other grains. It is the core equipment of food cleaning section. It can rub and

beat the dirt, wheat surface dirty and other impurities in the groin of wheat grain.

Can also be mixed in the wheatmud and poor strength of the disease deterioration of wheat grain broken separation, broken mortar, fine miscellaneous through the

arc screen plate hole separa tion, discharge through the ash mouth.

Friction Wheat Scourer for wheat cleaning in Wheat Maize Flour Milling Production Line- We provide integrated grain and Oil Engineering equipment EPC turnkey project from 100 TPD to 5000TPD Large sized milling lines.www.immyhitech.com

Friction Wheat Scourer

The WUXI HAEN Friction Wheat Scourer is a core wheat cleaning machine used in modern wheat flour production lines to remove surface impurities from wheat kernels before milling. In large flour mills ranging from 100 TPD to 5000 TPD, wheat often carries dust, soil, crease dirt, fungus spores, insect eggs, and pesticide residues. The WUXI HAEN Friction Wheat Scourer uses controlled friction between wheat kernels and the machine’s internal components to scrub and polish the grain surface, significantly improving wheat cleanliness and milling quality.

The working principle of the WUXI HAEN Friction Wheat Scourer is based on intensive mechanical friction. Wheat enters the scourer and is accelerated by a high-speed rotor. As kernels rub against each other and against a perforated screen, surface contaminants are loosened and removed. An aspiration system then extracts the separated impurities. This function makes the WUXI HAEN Friction Wheat Scourer highly effective as a pre-milling cleaning step in integrated grain engineering EPC turnkey projects.

In a standard wheat flour cleaning production line, the WUXI HAEN Friction Wheat Scourer is typically installed after preliminary cleaning equipment such as vibrating screens, magnetic separators, and destoners. At this stage, large impurities have already been removed, allowing the WUXI HAEN Friction Wheat Scourer to focus on deep surface cleaning. This positioning ensures maximum efficiency and protects downstream equipment such as dampeners, tempering bins, and roller mills.

The WUXI HAEN Friction Wheat Scourer is specifically designed to remove stubborn surface impurities that cannot be eliminated by conventional screening. These include crease dirt, adhering mud, fungal spores, smut balls residue, insect eggs, and fine dust embedded in the wheat bran. By eliminating these contaminants, the WUXI HAEN Friction Wheat Scourer improves flour color, reduces ash content, and enhances food safety in high-capacity wheat milling systems.

Flour quality is directly influenced by the cleanliness of wheat entering the milling section, and the WUXI HAEN Friction Wheat Scourer plays a decisive role in this process. By thoroughly cleaning the wheat surface, it reduces bran contamination during grinding and minimizes microbial load. This leads to brighter flour color, more stable flour quality, and better end-product performance. For large milling lines from 100 TPD to 5000 TPD, the WUXI HAEN Friction Wheat Scourer ensures consistent quality at high throughput.

Yes, the WUXI HAEN Friction Wheat Scourer is engineered for both medium and large-scale wheat flour production lines, including EPC turnkey projects from 100 TPD up to 5000 TPD. Its robust design, high wear-resistant components, and adjustable operating parameters make it ideal for continuous industrial operation. In integrated grain and oil engineering equipment projects, the WUXI HAEN Friction Wheat Scourer delivers reliability, efficiency, and low maintenance costs.

The WUXI HAEN Friction Wheat Scourer works in harmony with wheat dampening and tempering systems by preparing a clean grain surface for uniform water absorption. When surface dirt and waxy layers are removed, moisture penetrates the wheat kernel more evenly during tempering. This improves bran toughness and endosperm friability, optimizing the milling process. As a result, the WUXI HAEN Friction Wheat Scourer contributes to higher extraction rates and energy savings.

Operationally, the WUXI HAEN Friction Wheat Scourer offers high cleaning efficiency, adjustable scouring intensity, and stable performance under heavy loads. Its enclosed design minimizes dust leakage, while efficient aspiration reduces environmental impact. These advantages make the WUXI HAEN Friction Wheat Scourer a preferred solution for modern flour mills focused on automation, hygiene, and sustainable production.

Choosing the WUXI HAEN Friction Wheat Scourer means selecting equipment backed by expertise in integrated grain and oil engineering EPC turnkey projects. From process design to installation and commissioning, the WUXI HAEN Friction Wheat Scourer fits seamlessly into advanced wheat flour cleaning production lines. Combined with engineering know-how and large-scale project experience, it supports efficient, reliable, and future-proof milling plants, as showcased on www.immyhitech.com.

Food safety is a critical requirement in global flour markets, and the WUXI HAEN Friction Wheat Scourer directly supports compliance with international standards. By removing microbial contamination and chemical residues from wheat surfaces, it reduces risks in the final flour. In export-oriented milling operations, the WUXI HAEN Friction Wheat Scourer helps meet stringent hygiene, traceability, and quality control requirements.

For professional solutions in wheat cleaning and large-scale flour milling projects, please contact with WUXI HASEN For Friction Wheat Scourer to learn more about integrated grain and oil engineering equipment EPC turnkey projects from 100 TPD to 5000 TPD and advanced wheat flour cleaning production lines.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000