Vibration Screen used for wheat, barley, rye, oats, corn, rice, soybean, sorghum and other cereals secondary cleaning Suitable for wharf grain storage and logistics, flour, rice, oil, grain depot, wine and other industries.www.immyhitech.com

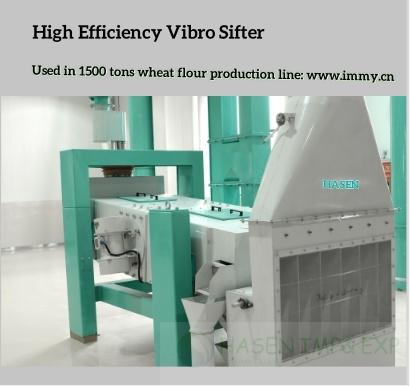

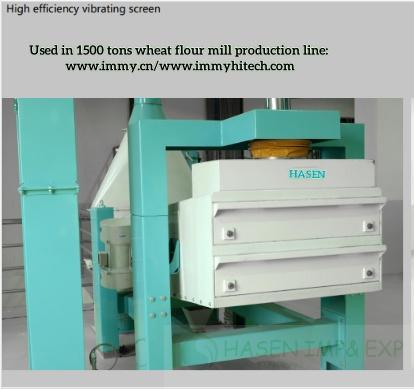

VIBRATION SIFTER HIGH EFFICIENCY

Vibration Screen used for wheat, barley, rye, oats, corn, rice, soybean, sorghum and other cereals secondary cleaning Suitable for wharf grain storage and logistics, flour, rice, oil, grain depot, wine and other industries. www.immy.cn/ www.immyhitech.com

Vibration Screen used for wheat, barley, rye, oats, corn, rice, soybean, sorghum and other cereals secondary cleaning Suitable for wharf grain storage and logistics, flour, rice, oil, grain depot, wine and other industries.

Application field:

Vibrating screen is an excellent performance of grain cleaning equipment, application and wheat, barley, rye, oats, corn, rice, soybean, sorghum and other cereals secondary cleaning Suitable for wharf grain storage and logistics, flour, rice, oil, grain depot, wine and other industries. The rotary vibrator is the best solution for grain cleaning when paired with the Primary shaker for Symex.

The machine can be used independently or with vertical air suction separator and self-circulating air separator, which can effectively separate light impurities

A vibration screen, also called a vibration sifter, is a key piece of equipment used for secondary cleaning in grain milling systems to remove impurities such as dust, husk fragments, broken grains, stones, and oversized materials. In modern grain processing plants, the WUXI HAEN Vibration sifter ensures that wheat, barley, rye, oats, corn, rice, soybean, sorghum, and other cereals are cleaned efficiently before milling, improving product quality and downstream processing stability.

A vibration sifter operates by using vibration motors to generate controlled oscillation that moves grain evenly across layered sieve decks. As material travels across the screen, particles smaller than the mesh pass through, while larger impurities are discharged separately. The WUXI HAEN Vibration sifter uses optimized vibration frequency and amplitude to ensure high screening accuracy while preventing grain damage during grain milling operations.

Secondary cleaning is critical after primary cleaning to remove fine impurities that can affect flour quality, milling yield, and equipment lifespan. The WUXI HAEN Vibration sifter provides precise separation of light impurities, broken kernels, and dust, ensuring cleaner raw material for flour, rice, oil, and feed production while meeting food safety and quality standards.

A vibration screen is suitable for a wide range of cereals and oilseeds, including wheat, barley, rye, oats, corn, rice, soybean, sorghum, and other grains. The WUXI HAEN Vibration sifter is designed with adjustable screen layers and mesh sizes, making it adaptable to different grain characteristics, moisture levels, and processing requirements in grain milling systems.

Yes, vibration sifters are widely used in wharf grain storage and logistics for pre-cleaning and secondary cleaning during bulk handling. The WUXI HAEN Vibration sifter offers robust construction, stable vibration, and high throughput, making it ideal for continuous operation in ports, silos, and grain transfer stations where efficiency and reliability are critical.

Clean raw grain directly impacts flour whiteness, rice yield, and final product consistency. By removing fine impurities and broken materials, the WUXI HAEN Vibration sifter helps reduce ash content in flour, improve rice appearance, and enhance milling performance across flour mills and rice processing plants.

In oilseed processing, removing impurities before crushing improves oil extraction efficiency and protects downstream equipment. The WUXI HAEN Vibration sifter effectively separates dust, stems, and foreign materials from soybeans and other oilseeds, supporting stable operation in oil mills and grain depots.

Yes, vibration sifters can be customized in terms of capacity, number of sieve layers, mesh size, and discharge configuration. The WUXI HAEN Vibration sifter is engineered to integrate seamlessly into existing grain milling systems, whether for small grain depots or large-scale industrial processing lines.

Vibration frequency determines material movement speed and separation accuracy. Too low reduces throughput, while too high may damage grains. The WUXI HAEN Vibration sifter is designed with optimized vibration parameters to balance efficiency and gentle handling, ensuring high screening performance for various cereals.

Compared to manual or static screening methods, vibration screens offer higher efficiency, consistent quality, and lower labor costs. The WUXI HAEN Vibration sifter provides automated, continuous operation with uniform material distribution, making it ideal for modern grain milling systems and logistics environments.

Modern vibration sifters are designed for low energy consumption while maintaining high throughput. The WUXI HAEN Vibration sifter uses high-efficiency vibration motors and balanced structures to minimize power usage, making it a cost-effective solution for long-term grain processing operations.

Removing stones, metal fragments, and oversized impurities prevents damage to rollers, grinders, and conveyors. The WUXI HAEN Vibration sifter acts as a protective barrier in grain milling systems, reducing maintenance costs and extending equipment lifespan.

Yes, vibration screens are suitable for both medium and high-capacity operations. The WUXI HAEN Vibration sifter is engineered to handle large volumes of grain continuously, making it suitable for industrial flour mills, rice mills, ports, and large grain storage facilities.

Routine maintenance mainly involves checking screen meshes, vibration motors, and fasteners. The WUXI HAEN Vibration sifter features a user-friendly design with easy access to key components, reducing downtime and ensuring stable operation in grain milling systems.

For more technical details, applications, and solutions related to vibration screens and sifters for grain milling systems, you can visit www.immyhitech.com. The WUXI HAEN Vibration sifter solutions showcased there are designed for cereals secondary cleaning across multiple industries.

The vibration screen plays a vital role in ensuring clean, safe, and high-quality grain processing across wharf logistics, flour, rice, oil, grain depot, wine, and other industries. The WUXI HAEN Vibration sifter stands out for its efficiency, reliability, and adaptability in modern grain milling systems. Please contact with WUXI HASEN For Vibration sifter to receive professional guidance and customized solutions for your grain processing needs.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:15354292@qq.com

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000